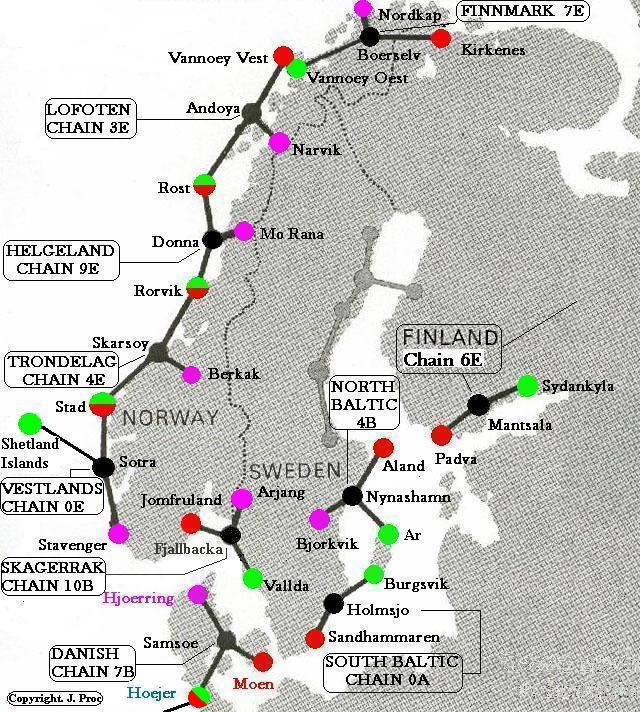

The new generation of Decca Navigator automatic transmitters

supplied to Norway were designed to operate unmanned with the transmitters

of each chain continually monitored and under remote control manned by

one person.

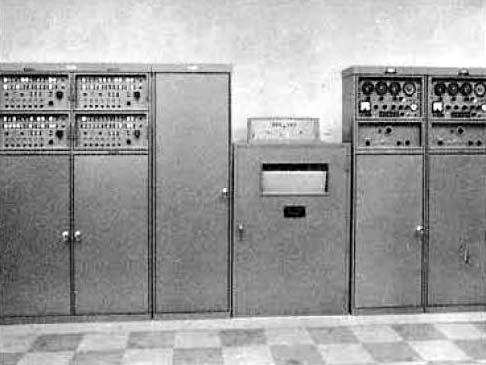

Each station was equipped with a Data Logger which scans all critical

units at regular intervals and records their serviceability state on punched

tape. From this surveillance, comprehensive information about the station's

functions are extracted for transmission and display at the control centre.

The control center has a duty engineer in attendance during the day and

is connected by an alarm system to the engineer's residence. The primary

equipment at the centre is the remote control console into which a continuous

a continuous flow of data from the transmitters is fed and displayed.

Command signals from the Centre to the out stations are transmitted

by the chain to the chain master station either by direct landline or by

radio link. Intervention by the chain engineer in the functioning of a

distant slave or master

station is made possible by the remote control system, the purpose

of which is to encode commands for transmission to the outlying transmitter

stations and decode messages from these stations.

Since an unmanned transmitter station is a relatively complex system

require to operate continuously, it is necessary to provide a day to day

record of the efficiency of all the major units and critical sub-assemblies.

This function is carried out by the Data Logger, one of which is installed

at each station and at the control centre as well. The Data Logger has

a capability of sending 183 bits of information covering all the vital

units of the transmitter and presents the information on standard five

hole punched tape which can be rapidly analyzed by an engineer during routine

or emergency servicing calls.

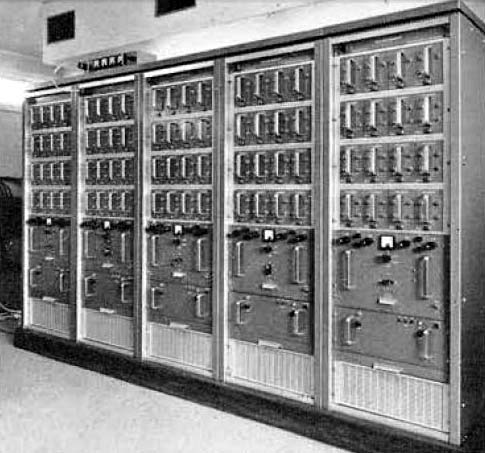

At the heart of the remote control station is the remote control and

display console which provides the duty engineer with a continuous overall

picture of the operating state of the master and slave stations. To enable

fault conditions to be dealth with immediately, a number of command functions

can be initiated from the console; these include a change over of the duty

phase control unit, reset and complete override of the phase control unit

automatic selection system, switch off of lane identification signals and

switch off of the entire station. To prevent inadvertent or incorrect use,

a test transmission must first be made and received back on the coloured

light display before the actual command transmission is made by operating

a pushbutton beneath the 'lift to operate' push-button flap.

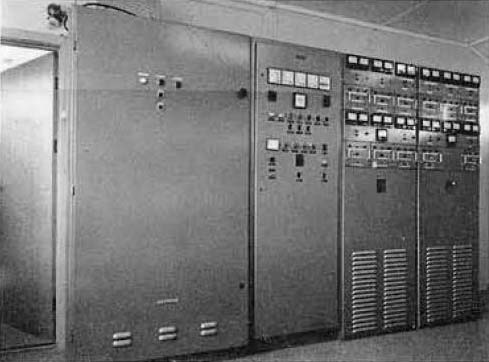

To provide a permanent record of the position-fixing and lane identification

readout by the chain, the control centre is equipped with a multi-pen recorder.

This 14 channel recorder produces a continuous analogue chart of the red.

green and purple patterns in addition to the lane identification transmissions.

A further six channels monitor the pattern torque level thus giving

an indication of the loss of any transmission. Two additional channels

carry 5 minute and 1 hour time markers.