|

| This

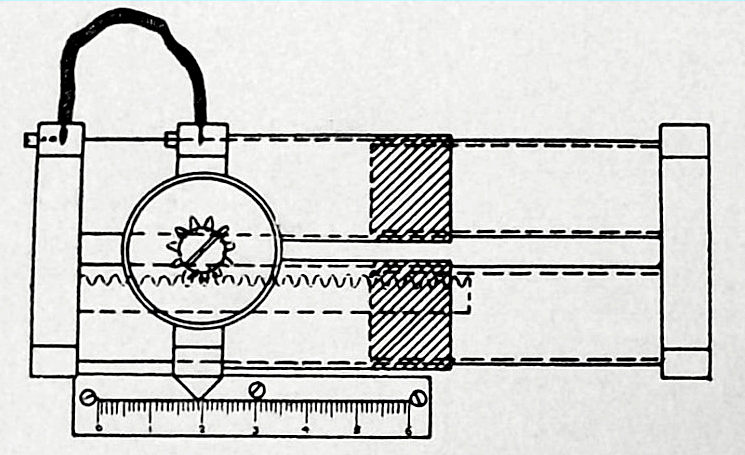

is a rack and pinion type of Billi condenser. Two brass tubes slide over

thin ebonite tubes inside which are brass plugs. The brass tubes and plugs

are the conductors, and the ebonite is the dielectric. The capacity of

course depends on the area of the opposing metallic surfaces and the thickness

of the ebonite. The active portion is shaded in this diagram.

For purposes of adjusting the capacitance, the tubes are given a quick movement by means of a rack and pinion fitting. One and a half turns of the milled ebonite head on the stem of the pinion carries the tubes the full length of travel which is six centimetres . For calibrating the condenser, the tubes carry a brass index and an ivorine scale of centimetres is fixed on the base below. The minimum and maximum capacitance of such a condenser is .00002 µf and .00045 .µf respectively. (Extract from Handbook of Technical Instruction For Wireless Telegraphists) . |