EQUIPMENT DESCRIPTION FOR 1957

AN/SCG-1 A radioteletype terminal set. See

description in 1962 section.

CSR5A receiver. See description in 1962 section.

FSC107 Frequency Shift Converter. See description in 1962 section.

Model SFO Teletype Regenerator.

|

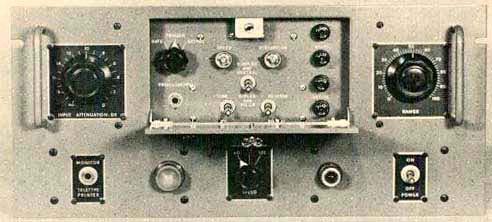

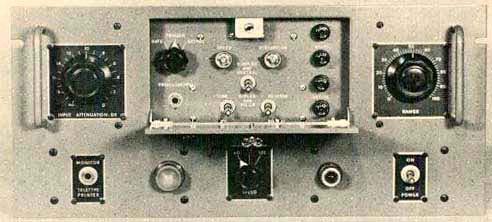

| Model SFO teletype regenerator. The front panel

door in the down position. (Photo courtesy TMC) |

According to BRCN 5422 , bias distortion is the lengthening of the mark

or space signal at the expense of the other. For an acceptable minimum

amount of errors, the teletype signal must not have more than 5% bias distortion.

There are three sources that contribute to distortion - mechanical, electrical

and propagation., however BRCN 5422 dwells on the discriminator circuits

in the Frequency Shift Converter as being problematic.

To correct bias distortion, a regenerator was placed between the Frequency

Shift Converter and the teletype machine. The SFO is capable of accepting

teletype signals in audio (on-off) form or in direct current form (polar

and neutral) and having up to 45% bias distortion. When regenerated, the

output signal will have less than 5% distortion. Made by Technical Material

Corp.

SPECS

* Accepts 60, 75 and 100 wpm teletype signals.

* Input keying - 500 to 3 KHz tone, 30 ma polar, 60 ma neutral, simplex

or diplex

* Power input: 105 to 125 VAC, 50 to 60 Hz; 85 watts.

Once encrypted broadcast was introduced in 1962, the SFO

was no longer needed as the regeneration of a teletype signal was handled

by the KWR-37 crypto receiver.

SUMMARY OF FUNCTIONS circa 1962.

Radioteletype (abbreviated as RATT in the RCN) was already installed

in HMCS Buckingham in 1954 as recalled by Radio Op Denies Stapleton.

Over the next few years broadcasts were sent over the RATT circuit

along with the normal CW broadcast until all designated ships had RATT

capability and the system proven reliable.

Sitting on the table is the Model 14 Reperforator which allows

an operator to create a punched paper tape with a message on it.

This tape would then be mounted unto the Model 14TD (Transmitter- Distributor

aka tape reader) where it awaited transmission. Once the operator started

the tape reader, an electrical signal (Baudot code) was sent to Radio 2

via hardwired cable, That signal was then converted into RATT form by a

Frequency Shift Keyer which in turn keyed the 500 watt PV500 transmitter.

RATT broadcasts could also be copied on LF or HF and printed on

one of the two teleprinters. It was a case of copying one broadcast or

the other but not both. A thick, black jacketed cable permitted the

selection of either the LF or HF receiver output to the input of the Frequency

Shift Converter. Encrypted broadcasts were automatically decoded

by the KWR-37 on-line crypto receiver. Two of these were situated in racks

on the starboard side of the Message Centre. Unfortunately, examples

of the KWR-37 are unobtainable at this time,

Mounted on the port bulkhead of the Message Centre is the TT-23 Teletype

Distribution panel. Using patch cords terminated with male telephone jacks,

this facility permitted the radio ops to reconfigure the interconnection

of RATT equipment within the Message Centre to suit operational needs.

| 1.2.1 - AN/SGC1A Radioteletype Terminal Set

VHF and UHF radioteletype was used for short range fleet broadcasts in

the 225 to 400 MHz UHF band. It was very likely that the escort force commander

would want to have a UHF RATT circuit dedicated for his use with his screening

ships in addition to a tactical, UHF voice circuit. One contributor suggests

that RATT over UHF could have been used in harbour to relay broadcast messages

between the Command Message Centre and ships in port. Can anyone confirm?

(Photo

by Jerry Proc)

VHF and UHF radioteletype was used for short range fleet broadcasts in

the 225 to 400 MHz UHF band. It was very likely that the escort force commander

would want to have a UHF RATT circuit dedicated for his use with his screening

ships in addition to a tactical, UHF voice circuit. One contributor suggests

that RATT over UHF could have been used in harbour to relay broadcast messages

between the Command Message Centre and ships in port. Can anyone confirm?

(Photo

by Jerry Proc)

Also, was there any off-line encryption applied to these RATT over UHF

messages? Contact jerry.proc@sympatico.ca .

When a RATT message was to be transmitted, the teletype machine or paper

tape reader (T-D) would interrupt a DC current loop based on the elements

of the Baudot signalling code. The resulting pulses were applied to the

input of an audio oscillator within the terminal set. These pulses then

keyed the oscillator to produce either a 500 Hz or 700 Hz audio tone. When

the loop was closed a 700 Hz tone was produced. A 500 Hz tone was produced

when the loop was open. The 700 Hz tone was considered to be the MARK state

while the 500 Hertz tone was the SPACE state. Alternately opening and closing

the loop caused the output of the terminal set to toggle between 700 and

500 Hz, thus representing the Baudot code as a warbling audio tone. In

turn, the audio output was applied to the microphone input of an AM transmitter.

This method of keying the transmitter was called Audio Frequency Shift

Keying (AFSK) or "tone modulation" in its heyday.

When traffic was to be sent, a control signal from the SGC1A placed

the radio transmitter on the air until the messages had been transmitted.

This control signal was activated by striking the space bar on the Teletype

machine prior to sending traffic. Alternately, if the T-D was used was

the input source, the first character on the tape would have to be a space

character.

When receiving messages, the process was reversed. The SGC1A accepted

the incoming mark and space tones from an associated AM receiver such as

the AN/URR35A. These toggling tones ultimately controlled the keying of

the DC current loop. This terminal set was manufactured by the Remler Co.

Ltd. of San Francisco. The first examples of the AN/SGC1A were produced

in November of 1950. |

CSR5 Receiver

The sole purpose of this receiver was to receive high frequency RATT

signals which provided input to the frequency shift converter. Normally,

reception was crystal controlled, however, when crystals were not available,

the CSR5 tuning control had to constantly be readjusted to maintain proper

RATT reception. When CSR5 receivers were rack mounted, they were usually

powered with a Marconi WE11 rack mounted power supply. This supply only

operated from a 120 or 220 VAC power source. On HAIDA, a replica was constructed

to replace the WE-11 unit that was missing.

KWR-37 On-Line Crypto Receiver

|

| Code named JASON, the sole purpose of this unit was to automatically

decipher the encoded RATT fleet broadcasts. On the input side, it was connected

to the current loop output of a frequency shift converter. The output side

was connected to a Teletype. (Photo courtesy NSA) |

|

|

The interconnection of the KWR-37 to the radio equipment.

|

GENERAL INFORMATION

The shore station started each day's broadcast at 0000 Zulu and transmitted

without interruption for 23 hours and 55 minutes each day. On shore, the

encryption device such as a KWT-37 was synchronized with a time signal

station (CHU or WWV) and the originating device sent an automatic 'start'

signal followed by a continuous stream of encrypted, non-repeating traffic

throughout the day.

The decoding 'key' which was similar to an IBM style punch card had

a pattern of randomly punched holes, and had to be changed daily, prior

to the start of the next day's broadcast. Encryption keys were changed

by unlocking a front door on the KWR-37, removing the existing card, and

installing the card that was designated for the next day. These cards were

inserted behind a small door in the front of the KWR-37 using the built-in

alignment pins. The door closed against a block of small, spring-loaded

steel pins. Where a pin touched the paper card, no signal passed; where

a pin poked through a hole in the card and touched a silver-plated metallic

track, a circuit was made. Each card held enough keys to cover 14 years

of usage before the key repeated itself. For very confidential messages,

the fleet broadcasts consisted of encapsulated five character cypher groups

which had to be decoded manually on a KL7 crypto unit. An example of this

type of message would be the notification of death of a crew member's next-of-kin.

Sometimes, there were periods were no messages were being sent on the Fleet

broadcast and the Teletype would just sit there receiving null characters.

John Dill of Kingsville Texas, was a crypto machine mechanic in the

USN in the 1960's and 70's, and kindly documented his experiences with

the KWR-37. "The holes in the punched cards directed the key stream to

a series of bistable multivibrators (flip-flops) which were wired on thirteen

printed circuit boards located on the left side of the machine when one

opened the equipment drawer. All the flip-flops plugged into a motherboard

which was positioned horizontally. The active devices in these circuits

were sub-miniature, type 6088, wire lead, sharp cutoff pentodes made by

Raytheon or General Electric. These tubes were about 5/16 inch in diameter

and 1 1/4 inches long and anchored by metal clips on each circuit board.

The 6088 pentode was also known as type CK522AX. Depending on circuit design,

the 6088 could be driven to produce as much as 10.5 mw of power at the

high end or as little as 1.2 mw at the low end! One multivibrator stage

consisted of two 6088 pentodes for the flip-flop and one 6814 sub-miniature

triode amplifier, a vacuum tube originally designed for late generation

tube computers. All stages had to be perfectly balanced, hence the use

of resistors with 1% tolerance. Typically, the pentodes ran at 67.5 volts

B+ and the triodes at 100 volts. There were four flip-flops per board and

the entire unit contained approximately 500 tubes.

In addition to the operational key cards, there were also cards used

strictly for testing. Each card in the test deck, checked a different KWR-37

function. Two of the cards, produced a distinctive pattern of beeps to

indicate proper operation and the technician had to listen attentively.

Used, operational cards were destroyed on periodic basis with two people

witnessing their destruction, depending on the specific 'customer'. With

care, the test cards could last for years.

The door for the key card was equipped with a lock in order to prevent

anyone but authorized personnel from seeing the punch card. For security

reasons, the card door was made from very thick steel. Details about the

construction of this door are still classified since a similar arrangement

was used on some newer machines. Affixed to the door, was a small placard

with the letters NOF. This stood for 'Not for Observation by Foreign national'.

It was permissible for a foreign national to view the front of the machine,

but that same person would have to leave the premises if the front door

of the '37 was opened for any reason.

When the '37 was first designed, an 'order wire' mode was incorporated.

It was intended to pass plain text instructions to the distant station

in order to bring up the system in crypto mode. These instructions were

to be passed in the clear using code words. When the '37 went into service,

the order wire was actually disabled.

OPERATION

Transmissions began at 0000Z and continued without pause or repetition

for 23 hours, 55 minutes each day. Whether any messages were being sent

or not, the 'customers' KWR-37's were on-line, in sync and receiving the

transmitted key stream. In the event of a power loss or if the unit went

out of sync, the operator would have to initiate a restart. When the sending

station stopped transmitting, all receiving units worldwide would be prepared

to receive transmissions for the next day. If radio conditions were normal,

the transmitting station's Auto Start signal would automatically start

the machine. If Auto Start was missed due to atmospherics, the operator

had to late start the unit. This procedure is discussed further in the

text.

On the front panel of the unit, there was a control composed of two

concentric dials; the outer for hours and the inner one for minutes. Above

that, were three miniature switches marked Start, Reset and Sync. Two small,

orange lamps tagged Mark and Space flashed alternately in time with the

incoming signal. Re- synchronization of the KWR-37 required that the machine

be reset, then run it forward in time at high speed to catch up to, then

slightly pass, the transmitting station's key stream. The operator would

set the Hours/Minutes dials to the difference between 0000Z and the current

Zulu time. The Hours dial was marked in 1 hour increments up to 23. Similarly,

the Minutes dial was marked in 5 minute increments up to 55. The Reset

switch would then be pressed. This would reset the flip-flops in the Key

Generator and the Internal Clock and ensure that all these circuits started

up from a desired, known, pre-set value. Internally, the reset signal was

routed to the flip-flop stages through the Key Card, thus changing the

initial 'set' state of the Key Generator. Pressing the Start switch would

enable and start the clock which began to drive the flip-flop stages thus

producing the key stream. Activating the Sync switch would give approximately

15 seconds worth of high clock speed, akin to a fast forward function.

If for example, the KWR-37 had dropped off-line at 14 hours into the

broadcast day due to loss of ships mains power, and restoral took 15 minutes,

the operator would set 14 hours, 15 minutes on the dials and hit the Start

button. The machine would run in high speed for several minutes until the

clock had advanced the key stream 14 hours and 15 minutes, at which time

it would drop back down to normal speed and start searching for sync. This

process forced the KWR-37 in constantly comparing it's own internal timing

to that which was being sent on the broadcast. If a clock comparison was

unsuccessful, the clock would delete a pulse, effectively dropping it back

in time by a small amount. Each time this pulse deletion occurred, an audible

beep was sounded through a panel mounted speaker. As the beep rate slowed,

it told the operator that synchronization was approaching. After several

seconds of silence the Sync light would illuminate and the Teletype attached

to the '37 would start printing.

If the search for synchronization ran over several minutes duration,

the '37 would alarm again with a steady, irritating, much-hated tone from

the speaker along with the dreaded red Alarm light. Standard procedure

called for resetting the machine and trying again. Since no two KWR-37's

were exactly alike, the presence of the alarm did not mean that the machine

stopped searching for sync. The alarm simply meant that the allotted amount

of time had elapsed, during which, synchronization should have been attained.

In many cases, the '37 achieved sync with the alarm sounding and the SYNC

light on. At this moment, the operator would silence the speaker and everything

would run normally. This was the official procedure for achieving synchronization.

In practice, however, it was an entirely different world. An operator

would generally attempt the formal procedure. If this did not achieve results,

a whole series of 'homebrew' remedies could be applied. Among these miracle

cures for lack of sync were: a) Pounding the front panel briskly just prior

to pressing the START switch.

b) Opening the equipment drawer and hitting the tops of the circuit

boards with some hard object such as a mallet or cleaning brush.

c) Opening the front door; removing the key card and cleaning the conductive

tracks in the rear of the front door with a rubber eraser. This practice

removed the plated silver on the tracks and was frowned upon.

d) Cleaning the conductive tracks with Teletype paper or paper money.

Since Teletype paper contained trace amounts of oil to assist with lubrication,

this practice was highly discouraged.

e) Rapid and vigorous spinning of the time-delay dials, followed by

many shots on the RESET button.

f) Uttering foul, abusive language at the machine in order to let it

know who was in charge.

MAINTENANCE

The KWR-37 was very old, tired and well past it's design life in 1968

and did not improve with age. Many technicians only had a modicum of training

in the art of soldering. For the '37 family, this was a disaster as the

most frequently performed corrective maintenance involved the replacement

of wire lead vacuum tubes. One can only imagine the damage that was done

to the printed circuit boards after 20 years of mediocre maintenance.

To ensure the highest reliability, crypto mechanics tried to turn out

a machine capable of operating normally with only 1 volt of filament voltage

to all the 6088 pentodes. The standard setting was 1.25 volts and was indicated

by a front panel meter. Each pentode had a filament draw of 20 ma. If the

unit ran properly at a reduced filament voltage, that meant that the tubes

had strong emission and the unit would run reliably. As emission decreased,

the operator could increment the filament voltage to restore normal operation.

When the machine became unreliable at a setting of 1.25 volts, it was turned

back to the maintenance depot. Checking for operation at a reduced filament

voltage became known as margining. The 6814 triodes which used indirectly

heated 6.3 volt filaments were not margined.

Later and unofficially, an extender board was developed which allowed

individual circuit boards to be margined. Once each board ran reliably

at one volt filament voltage, the filament supply to the entire machine

was reduced. If it worked, it was considered ready for use. Testing each

board individually improved the quality of the troubleshooting process.

The majority of maintenance problems in the '37 originated in three areas

of the machine: the 'S' circuit cards, (the ones containing the key stream

flip-flops); the 'T' cards which combined the 'S' card outputs and the

'U' or alarm cards. Next, were the cards which allowed the '37 to run at

high speed. The modified card extender was invaluable in finding these

circuit faults and eventually won official approval. A maintenance bulletin

was circulated among all KWR-37 holders documenting the modified extender,

the construction details and stock numbers of the parts required".

John goes on to comment about his worst KWR-37 repair job." A technician

had the '37 drawer open for maintenance. Innocently, a brand new Ensign,

who was the Communications Officer noticed the activity and came over for

a look. He must have been having a hard time at sea because of the large

bottle of Maalox (stomach antacid) in his shirt pocket. As the Ensign leaned

over to peek at the '37, the bottle fell out and broke on the top edge

of the equipment drawer. Needless to say, the Maalox spilled throughout

the machine and a large blue flash ensued as the power supply shorted out.

Flames and smoke began issuing from the drawer. The tech had been sitting

on the deck in front of the '37 cross-legged with his legs underneath the

extended drawer. His burning trousers were quickly extinguished by the

remainder of the Maalox running out of the equipment. In his haste to escape,

the tech placed his full weight on the card rack and broke the motherboard

in several places. The '37 was eventually repaired but the cost to repair,

likely exceeded the value of the machine".

Mechanically, the '37 was about 22 inches wide, around 24 inches deep

and 8 to 9 inches high with a case finished in navy cabinet grey. It was

usually positioned on an equipment shelf. With a weight approaching 100

pounds, it was definitely a two man lift when it was being installed. All

cabling plugged into the back of the unit.

OPERATING THE KWR-37 IN THE RCN

In the RCN, there was one minor difference in the manner that the KWR-37

machines were operated. Gregory Mclean of Abbotsford BC details the difference

and explains some operating practices. "In the RCN, the crypto cards were

not destroyed daily. At the end of each month, when we had finished with

that months pack, we returned them to the C.B. Officer (Confidential Book

Officer). To ensure separation of duties, the CBO was not involved in communications.

He was usually a junior officer with a number of unrelated duties. It was

up to him to destroy used crypto and other classified materials at predetermined

times. Sometimes, he requested help from communications branch personnel.

On smaller ships, the CBO could be the Communications Officer.

The KWR-37's went out of sync frequently. Static or other interference

could cause the machine to loose sync. One did not have to actually hear

the hateful 'out of sync beeping'. You knew you had a problem when the

teletype machine began printing garbage. It was possible to tell just from

the sound. The MARK and SPACE lights on the face of the '37 flashed in

sync with the incoming radioteletype signal. When out of sync, they glowed

continuously and gloatingly.

In some installations, where diversity reception was fitted, two '37's

copied the same broadcast on two different frequencies. It was rare to

lose both signals simultaneously but if the entire broadcast was lost,

and were in company with other ships, we could ask another ship for any

of the missed messages. Alternately, reruns of the specific messages could

be requested from the shore station. Sometimes, if a jackstay transfer

was scheduled, the other ship could pass the missed messages by jackstay.

We could not pass lost messages intership because intership crypto used

an off-line machine and that could compromise the on-line system. If travelling

alone, or everybody missed the messages, one ship would request the shore

station, via ship-shore circuit, to rebroadcast the missing messages by

referencing their sequence numbers.

I took my maintenance and repair course in Stadacona. We did six weeks

in a secure room. There were no notes and nothing could be taken from the

room. The exams were of the open book variety. On board ship when one had

exhausted all means of repairing a blinking, beeping KWR, you shut it off.

Sometimes when you turned it back on it worked fine. Other times, I exchanged

certain circuit cards from a good machine to the unruly one. Cleaning the

contacts behind the card door seldom worked. Sometimes we found small cracks

in the key cards. We really did not have the proper equipment to repair

37's at sea".

During it's service life, the security of the KWR-37 system was

essentially compromised from 1968 to 1985. When the USS Pueblo was captured

in 1968, the north Koreans acquired fully working KWR-37's along with active

key cards. (The Pueblo was a spy ship that went on a routine ELINT

mission down the North Korean coast).

Naturally, there was a mad scramble to quickly change all of the cards

held by KWR-37 'customers' all over the world. In the mid 1980's, it was

discovered that the infamous 'Walker spy ring' was selling active key lists

(ie the actual IBM style punched cards) to the Communists. It must

be assumed that this activity had trasnspired as early as 1968. Once again,

the key lists had to be quickly changed. It's important to note that simply

possessing a machine was insufficient to copy the traffic in the short

term. Any adversary had to be in possession of the active key lists in

order to immediately decode any traffic. When the ship was captured, the

crew had no way of quickly destroying the classified materials, so the

Koreans got it intact. When word got back to Washington that Pueblo was

captured with a full fit of materials, all hell broke loose, world wide.

By the early 1990's, any remaining KWR-37 crypto receivers were taken

out of service and destroyed. This sounds like a sad ending, but such is

life in the world of cryptography.

In 1962, aboard HAIDA, a pair of KWR-37's were fitted on steel racks,

and a canvas cover blocked them from view as the crypto receivers were

considered top secret. One device was assigned for HF/LF decoding while

the other unit served to decode UHF radioteletype traffic as implied by

the existing wiring. If a Radioman who had security clearance for the coding

systems left the RCN, it was mandatory that no information about the coding

systems be divulged for a period of six years. As with the KL7 crypto machines,

all of the KWR-37 crypto receivers fitted on Canadian ships was owned by

the National Security Agency of the United States and was loaned to North

Atlantic Treaty Organization member countries including Canada. 1.2.4

- Model 14 T-D (Transmitter-Distributor)A T-D is the official name for

what is otherwise a paper tape reader. Perforated paper tape was fed into

the transmitter- distributor for transmission of messages over a radio

link. The tape was positioned under a clip and over a lineup of 5 metallic

sensing pins. These pins opened or closed electrical contacts depending

on the presence of absence of holes. A sprocket wheel fed the tape past

the sensing pins and produced the Baudot code required for RATT transmission.

Model 14 Reperforator with Keyboard

A reperforator was a motor driven machine which generated punched paper

tapes either from the keyboard or upon receipt of Baudot code from another

device. Simultaneously, the unit printed the message on the tape. It is

worthy to note that the printing lagged the perforated holes by six characters.

Example - If the letter A was punched on the tape, it would be printed

a distance of six characters later. (Photo by Jerry Proc)

Messages could be prepared in advance and sent at routine times. This

would maximize system efficiency as the punched tapes could be checked

for accuracy prior to transmission. Some of the tapes were used to call

shore stations or other ships. Tapes could be formed into continuous loops

when multiple passes of the same message had to be sent. An example of

this would be a calling tape: CFH CFH de CGJD CGJD K . If these tapes became

worn out, the reperforator could be connected up to the paper tape reader

in order to regenerate the original tape.

Model 14 reperforators came in two types. They could either punch the

tape all the way through or leave a small paper hinge attached to the chad.

The tape produced by the latter type was called "chadless tape, since the

reperforator does not completely remove the circular piece of paper but

leaves it secured to the tape by a small uncut portion of paper. Chadless

tape had the advantage of tidiness but was somewhat awkward to roll up

by hand. In addition, this “chadless” feature was important to enable characters

to be printed on the tape six holes away from the associated character.

Chadless tape was the only type used at sea.

The RCN actually encouraged Radiomen to read the chad type tape and

encouraged them to keep a sample on hand at all times and study it during

their spare moments!

|

Model KSR 15 Teletype

A teletype is little more than an electrically operated typewriter.

The prefix tele means at a distance. Coupled with the word typewriter,

it forms a word meaning 'typewriting from a distance'. Model 15 machines,

originally installed around 1957, were capable of printing at 60 words

per minute. In 1962, they were replaced with faster Model 28's as a pre-requisite

for the new, now encrypted broadcast system called JASON. This system incorporated

the KWR37 on-line crypto receiver. For purposes of metering transmission

speed, a standard word was considered to be six characters in length.Normally,

Model 15's had to be checked weekly and receive a tune up every month.

The major maintenance interval was usually six months but could be shorter

than that, depending upon the amount of usage. Machines were usually refurbished

by returning the dirty or faulty mechanism back to a repair depot, removing

the signalling coils and motor, and immersing the remainder in a 45 gallon

drum of kerosene or diesel fuel for 24 hours. Several other drums would

serve as rinsing stations. The mechanism, was then left to dry, followed

by a complete tear down and inspection for badly worn or damaged parts.

It was easier to do it this way, as opposed to searching for worn parts

when the mechanism was in an assembled state. Afterwards, the mechanism

would receive a generous coat of lubricating oil, followed by mechanical

adjustments. Maintenance was normally handled by the " Green Empire" which

was the Electrical Branch of the Royal Canadian Navy. If machine adjustments

were required and the Green Empire was not available, then the adjustments

might be attempted by the radio operators. (Photo by Jerry Proc)

Click here to

see the Model KSR15 in action. (Recorded by Jim Brewer) |

There was one quirk about Teletype operation aboard ship. Because of

the plane in which the Model 15 was mounted, the carriage in the machine

would slow down in an upward pitching sea. Sometimes, the strain was so

much that the drive gears would strip! This problem was overcome with the

introduction of Model

28 teletypes. In this design, a bulky mechanical carriage was replaced

with a small, lightweight 'print block'.

In order to avoid fatigue while operating the Teletype, good posture

was very important. Function keys such as FIGS and LTRS could be very confusing

to use when compared with a regular typewriter. It became important for

the operator to practice and develop a good keyboard rhythm in order to

overcome these problems. From a signalling viewpoint, the RATT system used

the Baudot code in which mark and space conditions were converted to produce

a signal that had a frequency shift of 850 Hertz. Back in the 1950's and

1960's when tube receivers lacked good stability, it was necessary to use

a 'wide' frequency shift to compensate for receiver drifting. As receiver

designs improved, a frequency shift of as little as 170 Hertz became popular

because it used up less space in the radio spectrum. This became the standard

radioteletype 'shift' in the amateur radio bands and remains to this day.

There are still a few a few isolated commercial stations using wide shift

teletype, but these too, will eventually become obsolete.

Model 15 schematic can be found here.

MODEL 28 KSR TELETYPE

VHF and UHF radioteletype was used for short range fleet broadcasts in

the 225 to 400 MHz UHF band. It was very likely that the escort force commander

would want to have a UHF RATT circuit dedicated for his use with his screening

ships in addition to a tactical, UHF voice circuit. One contributor suggests

that RATT over UHF could have been used in harbour to relay broadcast messages

between the Command Message Centre and ships in port. Can anyone confirm?

(Photo

by Jerry Proc)

VHF and UHF radioteletype was used for short range fleet broadcasts in

the 225 to 400 MHz UHF band. It was very likely that the escort force commander

would want to have a UHF RATT circuit dedicated for his use with his screening

ships in addition to a tactical, UHF voice circuit. One contributor suggests

that RATT over UHF could have been used in harbour to relay broadcast messages

between the Command Message Centre and ships in port. Can anyone confirm?

(Photo

by Jerry Proc)

Designed in the 1930's, this six tube regenerative receiver was capable

of receiving signals between 15 and 600 kc. Tuning was accomplished through

the use of circular, geared logging scales for both coarse and fine tuning.

To determine an actual frequency, one had to look at the dial reading then

consult a 'tuning graph'. Since these graphs were not that accurate, most

operators calibrated the receiver by noting the dial positions after stations

of known frequency were identified. (Photo by Jerry Proc)

Designed in the 1930's, this six tube regenerative receiver was capable

of receiving signals between 15 and 600 kc. Tuning was accomplished through

the use of circular, geared logging scales for both coarse and fine tuning.

To determine an actual frequency, one had to look at the dial reading then

consult a 'tuning graph'. Since these graphs were not that accurate, most

operators calibrated the receiver by noting the dial positions after stations

of known frequency were identified. (Photo by Jerry Proc)

This unit converted RATT signals from either a CSR 5A or RAK receiver into

pulses which controlled a current loop. In the case of HAIDA, the FSC107

had a dedicated connection to one of the teleprinters through the Teletype

Distribution Panel. Audio input signals to this unit were represented with

2975/2125 hertz tones. The frequency difference between these tones is

850 Hz, hence defining the 'frequency shift' of the entire system. There

was a small CRT mounted in the 107 unit which was used to monitor the quality

of the received signal. (Photo by Jerry Proc)

This unit converted RATT signals from either a CSR 5A or RAK receiver into

pulses which controlled a current loop. In the case of HAIDA, the FSC107

had a dedicated connection to one of the teleprinters through the Teletype

Distribution Panel. Audio input signals to this unit were represented with

2975/2125 hertz tones. The frequency difference between these tones is

850 Hz, hence defining the 'frequency shift' of the entire system. There

was a small CRT mounted in the 107 unit which was used to monitor the quality

of the received signal. (Photo by Jerry Proc) The TT23-SG Teletype Panel was intended for general shipboard use to facilitate

the interconnection of various pieces of equipment such as teletypes, frequency

shift converters/keyers and tone terminals. There were six channels available

and each channel could have its loop current monitored and adjusted individually.

The Teletypes and the KWR-37's each had their own separate 'plug' boxes

which could be interconnected to the panel. Equipment interconnections

were dedicated and hardwired within the TT23. In case of equipment failure,

the connections could be re-configured with the use of patch cords. Northeastern

Engineering Inc. of Manchester, New Hampshire produced the first examples

of these units in 1947 for the US Navy Department. The unit installed on

HAIDA is S/N 182 dated 17/09/51. (Photo by Jerry Proc)

The TT23-SG Teletype Panel was intended for general shipboard use to facilitate

the interconnection of various pieces of equipment such as teletypes, frequency

shift converters/keyers and tone terminals. There were six channels available

and each channel could have its loop current monitored and adjusted individually.

The Teletypes and the KWR-37's each had their own separate 'plug' boxes

which could be interconnected to the panel. Equipment interconnections

were dedicated and hardwired within the TT23. In case of equipment failure,

the connections could be re-configured with the use of patch cords. Northeastern

Engineering Inc. of Manchester, New Hampshire produced the first examples

of these units in 1947 for the US Navy Department. The unit installed on

HAIDA is S/N 182 dated 17/09/51. (Photo by Jerry Proc)