RADIO ROOM 1 DESCRIPTION - 1957/1962 FITTING

1.1 - MAIN AREA

LOCATION: After of the upper mess deck, port passageway.

YEAR OF INSTALLATION : 1943. Modified in 1950, 1957 and 1962. Restored

in 1985. Enhancements to

the basic restoration continue as of Oct 1992.

CREW COMPLEMENT: 5 radio operators plus a watchkeeper

Staffing could consist of the following ranks:

P1RM - Petty Officer 1st Class Radioman

Dayman P2 - (did not stand watches. He would be a Petty Officer 2nd

class)

LSRM - Leading Seaman Radioman

ABRM - Able Seaman Radioman

Watchkeepers 3 OS - Ordinary Seamen

PURPOSE OF THIS ROOM: It was the main receiving and transmitting office

for the ship. It had LF (receive-only) , HF, VHF, UHF receive and transmit

capabilities.

TELEPHONE CONNECTIONS: Telephone D23 connects with Radio 4, the OPS

room and the bridge.

HISTORY:

1957

|

1957: Radio 1 as it appeared in 1957.

It is very close to the 1962 configuration. Two notable differences are:

1) The RAK receiver was moved from atop the operators console and

placed on its own shelf. It was used to guard the international distress

frequency of 500 KHz. 2) The FR12 xmtr-rcvr was sitting atop a stand on

the operator’s desk. Later, it was moved to its own shelf. Click on image

to enlarge (HAIDA archives drawing) |

1962

|

| June 2007: Starboard side view of Radio 1 looking forward.

Click on image to enlarge. (Photo by Jerry Proc) |

|

| June 2007: Port side view of Radio 1 looking aft. Click on image

to enlarge. (Photo by Jerry Proc) |

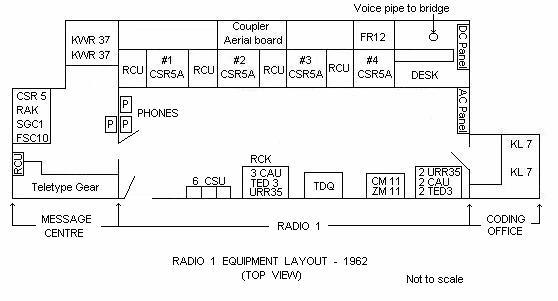

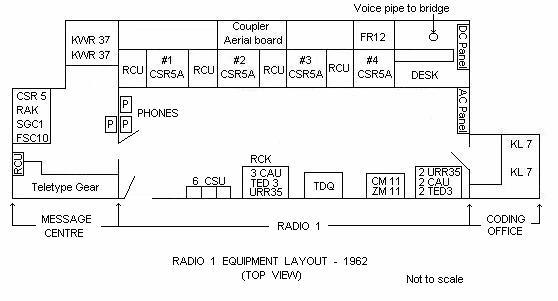

1962

|

| 1962 Equipment Layout Diagram of Radio 1 - Top view.. The Desk was

the Message Filing Area. (Graphic redrawn by Jim Brewer) |

|

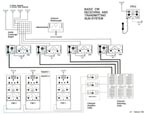

This pictorial illustrates the entire CW system

aboard HAIDA. Not counting the FR12, three HF CW circuits could be flashed

up if ever required. The two CW circuits in Radio 2 were remotely controlled

from Radio 1. Click on image to enlarge. Select

this link for a PDF version of the file. (Image drawn by Jerry

Proc) |

|

| Stew Patterson (standing) and ABRM Colin Blackburn at one of Morse

consoles around 1962. (Photo via Colin Blackburn) |

STAFFING

Although there were four operating positions in Radio 1, the

normal complement was one or two positions. According to Al Goodwin, HAIDA's

POTEL in the early 1960's, " I don't recall having all four positions filled.

If we had a new radioman on copying the broadcast, I might have someone

else double up with him until he got the drift of the job.

During a fleet exercise there were possibly three on watch. Once the

ship departed port we would operate around the clock, usually in

three watches. I had approximately six Leading Seamen and below ,

a PO2 and myself (PO1). I did not stand a watch".

DESCRIPTION OF EQUIPMENT

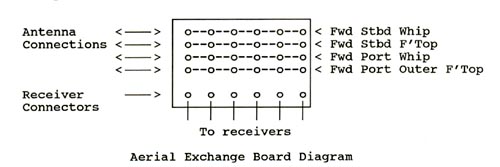

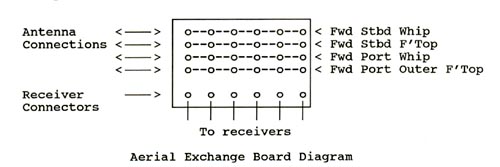

1.1.1 - Aerial Exchange Board

This was a matrix board composed of a grouping of SO-239 RF connectors

which permitted the interconnection of different receiving antennas to

the various receivers located in Radio 1. There are four antennas connected

to the coax connectors in the Y axis on the very left of the board. Each

of these connectors has additional parallel connections in the X axis.

At the bottom of the board, there are six connectors which attach to the

various receivers. Antennas were attached to receivers using one foot long

patch cords. The antennas connected to the Aerial Exchange Board were only

used for receiving.

|

| Aerial Exchange Board Diagram |

Why were there two receiving whip antennas installed? The first

reason would be redundancy - in case of damage. Secondarily, the radio

operators discovered that by having two whip antennas to choose from, it

gave them the ability to select the antenna which provided the best quality

of reception.

Sometimes, it was case where one whip would simply receive a little

better than the other so the better of the two would be selected. The overall

antenna architecture aboard ship was to have all of the high frequency

receiving antennas mounted forward and all transmitting antennas mounted

aft in order to provide maximum separation. HAIDA's four whip antennas

were painted white up to the first knuckle joint and black for the remainder.

The original reasoning for this may be obscure but logic dictates that

the lower part was white to conform to an overall colour scheme which dictated

that masts, derricks, etc., would be white. The upper part was black because

the antennas were exposed to funnel smoke and got very dirty. On a black

surface, the dirt wasn't as conspicuous.

Flattop (wire) antennas were rigged to a pulley system that was used

to raise and lower them. Very often when the ship was "dressed" the

lines from the foremast carrying the lights or flags or pennants interfered

with the flattops and so they had to be lowered out of the way.

|

This is a detailed view of the forward port whip

sponson aboard HAIDA . The ship was fitted with four 35 foot whip

antennas when she was in service. For unknown reasons, the two aft whips

were removed by the navy when HAIDA paid off. Eventually, 28 foot whip

antennas from paid off HMCS Mackenzie were located and installed on the

ship. Click on image to enlarge. (Photo by Jerry Proc) |

|

| Horizontally speaking, each row of SO-239

connectors are daisychained. Each row is connected to one of four antennas.

. (Photo by Jerry,Proc) |

| 1.1.2 - AMC-6-2 Antenna Multicoupler

As the requirement for additional radio channels grew during the 1950's,

it was important that each ship had separate receivers operating on many

different frequencies. Space had to found for all of the their respective

antennas so as to avoid mutual interference or interference from the ships

radar. One solution to this problem was the installation of an antenna

multicoupler.

As the requirement for additional radio channels grew during the 1950's,

it was important that each ship had separate receivers operating on many

different frequencies. Space had to found for all of the their respective

antennas so as to avoid mutual interference or interference from the ships

radar. One solution to this problem was the installation of an antenna

multicoupler.

Manufactured by TMC Limited (Ottawa) in 1953, this device is a broadband

RF amplifier which allowed a common antenna to drive up to six different

receivers in the range between 2 and 30 Mc. A switchable filter would provide

35 db attenuation against interference from signals below 1.5 Mc and each

output port provides 10 db gain when the filter is switched in. The unit

currently installed on HAIDA is not the original T164D type but it's authentic

enough for display purposes. (Photo by Jerry Proc)

|

1.1.3 - AN/URR35A Receiver

|

This was a double conversion, UHF, superheterodyne

receiver designed to receive AM or Modulated CW (MCW) signals in the 225

to 400 Mc band. The first intermediate frequency (IF) stages operate at

18.6 Mc while the second IF functions at 1.775 Mc. URR35's were always

slaved to the same TED3 transmitter, as the transmitter contains the antenna

changeover relay. Click on image to enlarge. (Photo by Jerry Proc) |

Receiver tuning was normally crystal controlled, however, a capacitor

could be used in lieu of a crystal under emergency conditions. To tune

the receiver under crystal control, the main tuning control was coarsely

set to match the frequency of the crystal. The tuning control would be

swept back and forth and left and locked in the position where the loudest

background noise was heard. There were four variations in the URR35 receiver

family:

URR35 and URR35A - Same except for minor changes in the value of two

resistors.

URR35B - This variant was fitted with a new blower and a plug/jack connector

in order to facilitate replacement. The value of the IF Gain control was

increased to provide better control.

URR35C - In this version, the scanning circuit and the SCAN connector

on the low pass filter were eliminated along with test cables included

with previous equipment. A few resistor values were also changed. All parts

were interchangeable with previous versions except for the low pass filter

assembly at the rear of the unit. There is no evidence at this time to

suggest that the RCN used the B or C variants.

AN/URR-504 was the designator applied to the receivers sold to the RCN

and made by Cossor Canada.

These receivers were of robust design both mechanically and electrically.

They had a tube count of twenty two and weighed 57 pounds.

The following standard RCN crystal frequencies

were available for the AN/URR-35 receiver.

|

| 1.1.4 - Channel Amplifier Unit - CAU

A bi-directional amplifier and control unit which amplified a remote audio

source and fed this to the audio input of a transmitter. In addition, it

would amplify audio output from a receiver and then feed it to a remote

location on the ship. CAU's were always used in conjunction with Channel

Switching Units and Remote Control Units. The model number of the CAU installed

on HAIDA is AM-5143/URA-501V(A). These are solid state (integrated circuit)

units which incorporate voice compression and were directly interchangeable

with the vacuum tube versions that were originally fitted on HAIDA.

A bi-directional amplifier and control unit which amplified a remote audio

source and fed this to the audio input of a transmitter. In addition, it

would amplify audio output from a receiver and then feed it to a remote

location on the ship. CAU's were always used in conjunction with Channel

Switching Units and Remote Control Units. The model number of the CAU installed

on HAIDA is AM-5143/URA-501V(A). These are solid state (integrated circuit)

units which incorporate voice compression and were directly interchangeable

with the vacuum tube versions that were originally fitted on HAIDA.

As originally designed, the CAU connects to a 32 post terminal board

located behind the unit and HAIDA is fitted with this terminal board system.

In later installations, the terminal board was replaced with a bulkhead

mounted, Amphenol Series 26 connector. As the CAU was slid into it's operating

position, the male connector on the CAU chassis would mate with the female

connector mounted on the bulkhead plate. When the CAU was withdrawn on

its runners for maintenance, a patching cord would be used to provide a

connection between the CAU and the rest of the system.

There was one internal CAU setting which needed to be changed and was

dependent upon the type of radio connecting to that CAU. Plug P511 is inserted

into socket S511 when the CAU is used with a LF/HF gear. This action causes

the audio input to be attenuated to the same level as that from a VHF/UHF

receiver. This same plug is inserted into S512 when the CAU is used with

VHF/UHF equipment. The audio to the transmitter was boosted by 10 db, while

the audio from the receiver was amplified by 30 db. When CAU's were attached

to CW or RATT transmitters, keying speeds were limited to 100 cps due to

cable length. (Photo by Jerry Proc) |

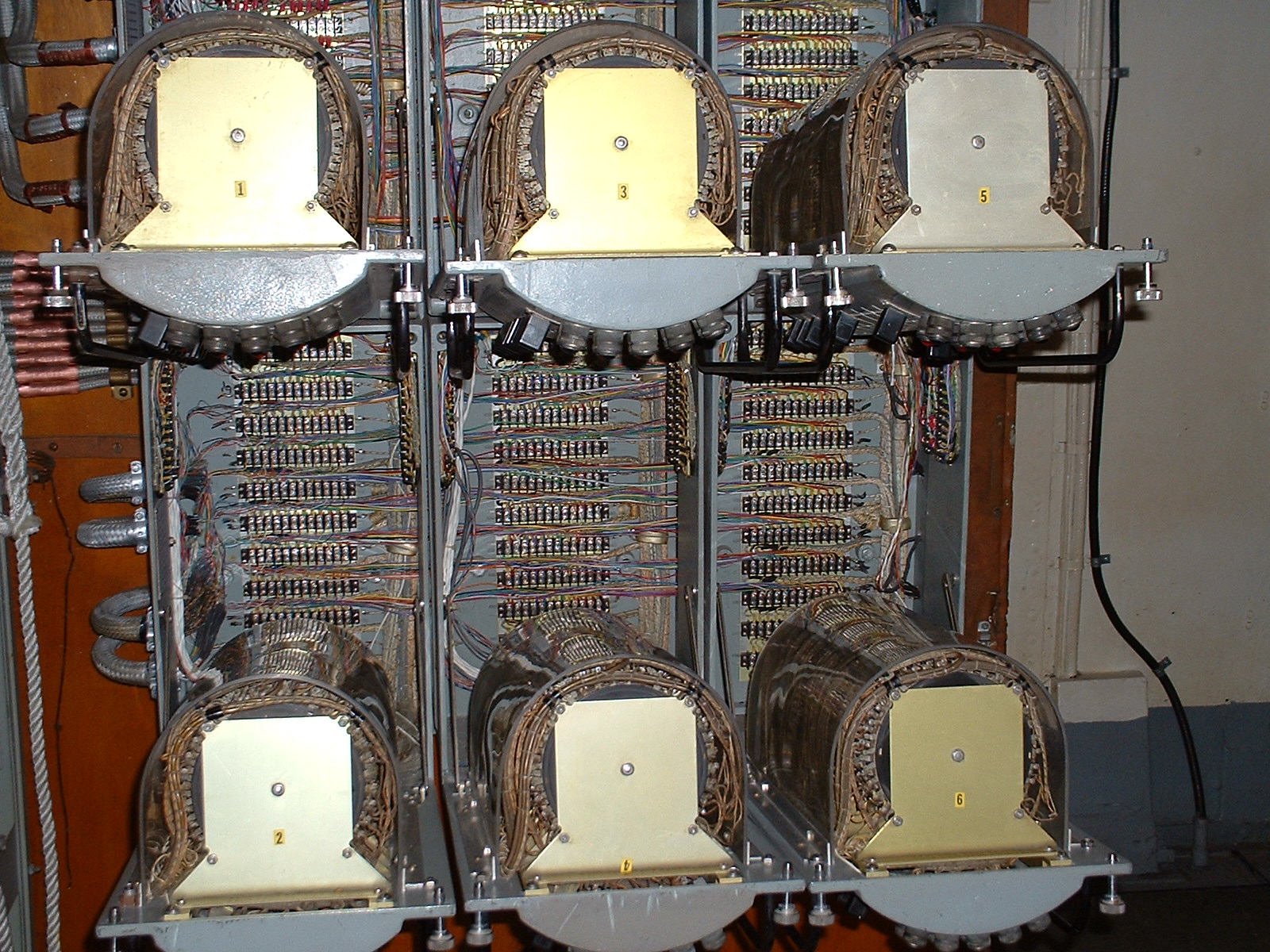

1.1.5 - Channel Switching Unit - CSU

|

| Informally, the CSU was known as the "Bread Slicer"

and was the heart of the Shipborne Radio Remote Control System. This device

allows up to ten different Remote Control Units to be switched or shared

between five different transmitter/receiver pairs. By moving a slide switch,

any RCU could be connected to any available radio channel. Once a slide

switch was set to a particular position, the RCU could only communicate

with one transmitter/receiver pair. Click on image to enlarge. (Photo

by Jerry Proc) |

|

| This is one of the CSU's in the swung down position.

There are 10 complex wafers in each of the six CSUs . Click on image to

enlarge. (Photo by John Paszkat) |

|

| This is how it looks with the six CSU's in the

open position. Click on image to enlarge. (Photo by Jerry Proc) |

The number of RCU connections or radio channel connections

to the CSU could be expanded through the use of an intermediate cable harness.

If more than ten RCU connections are required, a vertical intermediate

cable harness can be installed in order to daisy chain vertically adjacent

CSU's. This would allow additional RCU's to be shared with five radio channels.

Similarly, the installation of a horizontal intermediate harness could

be used to increase the number of available radio channels.

Mounted across the top of the CSU's are green and red lamps. Each green/red

pair provides channel status. RED means 'ready for transmission' while

GREEN indicates that the channel is 'transmitting'.

Another component of the remote control system was the Receiver Switching

Unit (RSU). This unit provided a means of switching any one of six receivers

to any one of five radio channels. When fitted, there could only be one

RSU for the whole system. RSU's were not used on HAIDA and are only mentioned

here for the sake of completeness. The CSU/RCU/CAU remote control system

was a Canadian development that worked very well and was admired by our

contemporaries in the Royal Navy and the United States Navy. All of the

radio remote control system was manufactured by Beaconing Optical and Precision

Materials Company (BOP) in Granby, Quebec. (Photo by Jerry Proc)

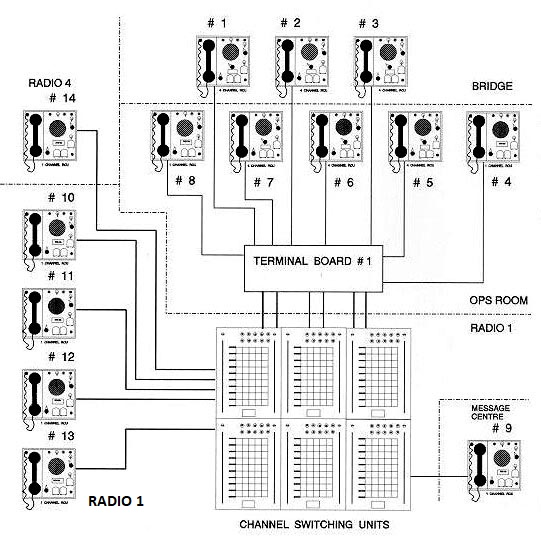

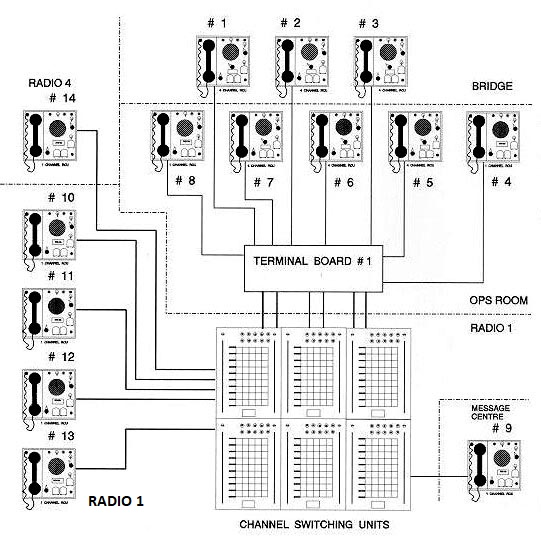

There are a total of fourteen RCUs connected to the CSUs. RCU's

1, 2, and 3 are on the Bridge. Units 4, 5, 6, 7 and 8 are in the Ops Room.

No. 9 is in the Message Centre. Nos 10, 11, 12 and 13 are in Radio

1 and lastly, No. 14 is in Radio 4. The Bridge and Ops Room are fitted

with four channel RCUs with the remainder being single channel units. Some

of the RCU are hardwired together. The following labelling appears on the

front of the CSUs:

9, 10, 11, 12, 13, 14

178-1, 17-2, 17-3, 17-4

26-1, 26-2, 26-3, 26-4,

345-1, 35-2, 35-3, 35-4

Here is a decode for two of the designations.

Example #1 178-1 means Channel 1 of RCUs 1, 7 and

8 are hardwired together.

Example #2 345-1 means that Channel 1 of RCUs 3,

4, and 5 are hardwired together.

Using slide switches on the CSU, any radio channel of interest can be

connected to single channel RCUs or the hardwired combinations on

the four channel RCUs.

|

Here, Jerry Proc (L) and Jim Brewer (R) are restoring

HAIDAs Radio RemoteCcontrol systen as featured in The Canadian Amateur

Magazine in Febryary 1996. It woul be a project that spammed

nime months of Saturdays to complete.

When HAIDA paid off, the navy severed all the cables which terminated

on the Channel Switching Units and the Remote Control Units. This was dome

to expedite the removal of the equipment. To get the system operational

again, it took some 4,000 wire splices and connections. The

best part was that it all worked when the system was flashed up. Click

on image to enlarge. (Photo courtesy Radio Ammeters of Canada) |

| 1.1.6 - CM11 Transmitter/Receiver

First built in 1942, the CM11 was a transmitter/receiver that was capable

of operation in the 375 kc to 13.5 Mc range. There were two distinct bands

of operation: 375 to 515 kc on low frequency and 1.5 to 13.5 Mc on high

frequency. In the high frequency band, the CM11 could be used with crystal

or master oscillator frequency control. For low band operation, only the

master oscillator could be used. The RCN labelled CM11 crystals with two

additional frequencies besides the fundamental - the second harmonic and

the third harmonic. The transmitter could be tuned to operate on any of

the three frequencies. Modes and power levels were: CW - 100 watts; MCW

- 70 watts; AM - 30 watts. The Signal Electric R63 was the key provided

with the CM11 - RCN pattern number 3M/103.

First built in 1942, the CM11 was a transmitter/receiver that was capable

of operation in the 375 kc to 13.5 Mc range. There were two distinct bands

of operation: 375 to 515 kc on low frequency and 1.5 to 13.5 Mc on high

frequency. In the high frequency band, the CM11 could be used with crystal

or master oscillator frequency control. For low band operation, only the

master oscillator could be used. The RCN labelled CM11 crystals with two

additional frequencies besides the fundamental - the second harmonic and

the third harmonic. The transmitter could be tuned to operate on any of

the three frequencies. Modes and power levels were: CW - 100 watts; MCW

- 70 watts; AM - 30 watts. The Signal Electric R63 was the key provided

with the CM11 - RCN pattern number 3M/103.

Inter-connection between the transmitter, receiver and antenna tuner

was provided by snatch plugs. These connectors operate on the same principle

as knife switches. Each of the three slide out units in the CM11 are equipped

with female snatch plugs. When slid into place, the antenna tuner, transmitter

and receiver interconnect through a wiring bus that is fitted with male

snatch plugs. When withdrawn for maintenance, patch cords had to be installed

between the transmitter or receiver and the bus. The CM11 antenna tuner

was a very versatile device, since it could match antennas that were 5

to 750 ohms resistive and supported operation in the range of 375 kc to

13.8 Mc.

The following standard RCN crystal

frequencies were available for the CM11 transmitter.

Keith Kennedy ex-C2NET(s) of Surrey BC notes that "the CM11 was notorious

for generating harmonics and spurious emissions and HMC Ships would routinely

receive harmful interference reports from the Department of Transport monitoring

station located at Wetawaskin Alberta. We had little in the way of test

equipment and certainly nothing as fancy as a spectrum analyzer so we just

followed the CM11 tuning instructions and filed the reports away. The CM11

was also known for its chirpy CW signal when controlled by the master oscillator

but it behaved properly under crystal control. CM11's also had a bad habit

becoming detuned as the ship rolled. It was the result of changing capacitance

between the antenna and the surface of the sea".

Gerry Taylor was a former RCN radio operator. He recalls his experiences

with the CM11 transmitter.

"My memory of the use of the CM-11 is pretty well limited to a only

a couple of ships that I served in. I mainly used it for sending and receiving

but I did have to know how to tune them up for the desired output

mode and frequency. I preferred to use it mostly on CW 100

watt output. The transmitter that we used the most for Navy Traffic

at sea was the PV500, which had a much higher wattage output.

The ship that I used the CM-11 on the most was HMCS Fort Erie,

in 1962. On that ship, we were on a three month cruise up and down

the West Coast of Africa, from Dakar Senegal to Lagos Nigeria. There

were two ships on that Cruise - the Fort Erie and the New Waterford.

We were supporting three Canadian Trade Fairs up and down the Coast. The

ship was licensed for ham radio, and the call sign was VE0NR. Not

a lot of military stuff going on during this cruise, and the CM-11 met

the legal limits for ham radio operation. A few times

we were able to connect with Ontario stations who made phone patches for

us to family members.

As I recall, the quality of the CM11's phone mode was not that

great. The reliability of the set seemed to be good. I can't remember

having any technical issues occurring during use. I liked the

tone of the CM-11 on CW output. On Modulated CW output, you got a

totally different tone as I recall. They clunked and made a lot of

noise. I cannot recall using anything other than the Master Oscillator

on the CM-11. The Main Radio Room had about 3 or four work stations

in a row. We would use one of the work station receivers to listen

to the CW conversation..”

On HAIDA's bridge, a SM11 remote radio telephone control unit can still

be seen. It was abandoned after the RCU/CSU/CAU radio remote control system

was installed. All of the CM11's fitted on HAIDA were connected to the

Shipborne Remote Control System and were keyed or controlled by the RCU's.

The power supply for the CM11 was very versatile, as it could operate

on 120/220 VAC or 24/36/220 VDC power sources. A fifteen second time delay

circuit prevented power from being applied to the transmitter in order

to protect the mercury vapour rectifiers. There was an emergency mode which

decreased the time delay to 4 seconds but at the expense of shorter mercury

rectifier life. Weighing in around 478 pounds, the CM11 just wasn't portable!

Eventually, the CM11 was superseded by the AN/URC32 transceiver. (Photo

by Jerry Proc)

|

| CM11 speaker. (Image source unknown) |

|

| 1.1.7 - CPRC-26 Transceiver

Designed by the Canadian Signals Research and Development Establishment

and manufactured by Rogers Majestic starting in 1951, this was the first

Canadian developed and built post World War II military radio.

Designed by the Canadian Signals Research and Development Establishment

and manufactured by Rogers Majestic starting in 1951, this was the first

Canadian developed and built post World War II military radio.

The CPRC-26 was a self-contained, battery operated, transceiver (walkie

talkie) which operated in the frequency range of 47.0 to 55.4 Mc. Its 300

milliwatt input is frequency modulated using a deviation of +/- 15 KHz.

Six, crystal controlled channels were available for communication. Power

was provided by a dry battery and a fresh unit would provide about 20 hours

of service. Normally, the CPRC-26 would be used with a 47 inch collapsible

whip antenna. It was a unique set for its time since it had replaceable

modules.

All RCN ships carried three CPRC-26 transceivers which were usually

kept in the main radio office. A communicator would carry one in a lifeboat

and with landing or boarding parties. Other uses included short term communication

between ships for such jobs as jack-stay transfers, underway fuelling and

shoots. It was an excellent means of communication between the bridge and

the emergency conning position during times of crisis. In total, there

were around 4,500 of these units built for NATO forces by Philips and Canadian

Rogers. By 1969, the RCN declared this gear as obsolete, dangerous or unreliable

depending on the source of information.

The following standard crystal frequencies

were available for the CPRC-26 :

Select this link for photos of the CPRC-26. |

| 1.1.8 - CSR 5A Receiver

First built by Canadian Marconi in 1942, this general coverage receiver

was capable of receiving AM and CW signals between 80 kc and 30 Mc with

the exception of the broadcast band. It had a tube count of thirteen and

weighed in at sixty eight pounds without power supply. CSR 5A's spent most

of their working life receiving the Fleet Broadcast or guarding the International

or marine distress frequencies. Each receiver was connected to its own

wall mounted speaker, but headphones were the order of the day. Loudspeakers

were used when one Radioman had to guard more than one frequency. This

was known as a loudspeaker watch.

First built by Canadian Marconi in 1942, this general coverage receiver

was capable of receiving AM and CW signals between 80 kc and 30 Mc with

the exception of the broadcast band. It had a tube count of thirteen and

weighed in at sixty eight pounds without power supply. CSR 5A's spent most

of their working life receiving the Fleet Broadcast or guarding the International

or marine distress frequencies. Each receiver was connected to its own

wall mounted speaker, but headphones were the order of the day. Loudspeakers

were used when one Radioman had to guard more than one frequency. This

was known as a loudspeaker watch.

A modification was made to this receiver by the RCN. The "F" band (80

to 200 kc) was adjusted 10 kc low to enable the reception of the broadcast

frequency of 73.6 kc. This frequency is still assigned to Maritime Command

as of 1994. The RCN also labelled CSR- 5A crystals with two additional

frequencies besides the fundamental - the second harmonic and the third

harmonic. The receiver could be tuned to operate on the fundamental or

the other two frequencies. One of the noted quirks of the CSR 5A was the

habit of going off frequency in rough weather when continuous tuning was

used. If a large wave hit the ship, it would overcome the friction of the

tuning gear assembly and knock the dial off frequency. There were no such

things as frequency synthesizers or phase locked loops in those days. The

vernier control would be used to retune the frequency.

In the CSR 5A, the band-switch assembly has been wired into a sub-chassis

which can be detached from the main chassis. This operation should be never

be attempted by the inexperienced. First, you extract the receiver from

its case and detach the bottom cover plates - do not be concerned over

the 30 screws that secure the plates. Next, desolder 29 connections as

outlined in the manual. Following that, there are another 20 screws to

remove in order to physically detach the RF turret. Do not go insane in

the process, or you won't be able to get the pieces back together. This

brief glimpse of 1942 radio maintenance has been presented for those readers

who have complaints about 1990's manufacturing methodology. (Photo by

Jerry Proc)

Much rarer, is the Marconi CSR5Y, a variant adapted for diversity reception.

Rather than having a toggle switch for the AVC, a three position rotary

switch is used. It is marked DIV, OFF and INT. The Send/Rcv switch is eliminated

since the receiver is intended to be in receive mode all the time. There

is also a terminal strip on the rear of the chassis marked AVC. The AVC

was probably derived from an external comparator when in Diversity mode.

In all other respects, the Y variant is identical to its more common cousin.

The CSR5Y would mostly likely be found in a shore installation. (Photo

courtesy Meir Ben-Dror, WF2U)

Much rarer, is the Marconi CSR5Y, a variant adapted for diversity reception.

Rather than having a toggle switch for the AVC, a three position rotary

switch is used. It is marked DIV, OFF and INT. The Send/Rcv switch is eliminated

since the receiver is intended to be in receive mode all the time. There

is also a terminal strip on the rear of the chassis marked AVC. The AVC

was probably derived from an external comparator when in Diversity mode.

In all other respects, the Y variant is identical to its more common cousin.

The CSR5Y would mostly likely be found in a shore installation. (Photo

courtesy Meir Ben-Dror, WF2U)

In July of 1992, there was only one functioning CSR 5A receiver

in Radio 1. During the winter of 1992/1993, four of the receivers were

repaired, refinished in the original colour of 50 years ago and refitted

with shock absorber assemblies. One receiver in particular, had ten faults

which required correction.

The VP3 power supply for the CSR 5A was designed to operate from 120/220

volt 50/60 Hz AC power or 12 VDC. When operating on DC power, some changes

had to be made. Marconi designed two power interlocks to ensure that no

damage could be caused by inadvertent operation on the wrong power source.

To switch from AC to DC operation, a five pin interlock plug had to be

moved from one socket to another. Subsequently, the AC line cord had to

be disconnected from the wall socket and inserted into a special chassis

mounted receptacle. VP3 power supplies also acquired a reputation for fusing

the contacts on the vibrator and frying the primary winding on the power

transformer. By 1969, the CSR 5A was considered obsolete and was taken

out of service.

In July of 1992, there was only one VP3 supply among four CSR 5A receivers.

Another VP3 was found in storage but was completely deteriorated and had

to be rebuilt from bare metal. Since three other VP3 power supplies were

missing, near replicas were constructed in order to restore operation to

the receivers.

The following standard RCN crystal

frequencies were available for the CSR5 receiver.

|

| 1.1.10 - RCK Receiver - AN/URR21

Weighing in at 117 lbs, the RCK was a 'low radiation' VHF receiver built

by E.H. Scott Radio Laboratories during the 1940's. Copious use of RF shielding

helped contribute to its hefty weight. The RCK had four crystal controlled

channels and operated in conjunction with the TDQ transmitter in the 110

to 160 Mc radio band. Also, there were nine sockets for storing additional

crystals.

Weighing in at 117 lbs, the RCK was a 'low radiation' VHF receiver built

by E.H. Scott Radio Laboratories during the 1940's. Copious use of RF shielding

helped contribute to its hefty weight. The RCK had four crystal controlled

channels and operated in conjunction with the TDQ transmitter in the 110

to 160 Mc radio band. Also, there were nine sockets for storing additional

crystals.

One unusual feature of the design was the tuning system. Normally, when

a receiver is under crystal control, the main tuning dial must be set to

the same frequency as the crystal. This is accomplished by sweeping the

dial back and forth across the operating frequency until the loudest background

noise is produced. In the RCK, there was a mechanical tuning mechanism

that could be preset so the main tuning dial hits a 'detent' position at

the exact frequency of operation. When this happened, a red channel indicator

light came on to show the channel number being received. If any of the

crystals were changed, and you wanted the use of the 'lamp on frequency'

feature, then a mechanical tuning assembly would have to be re-adjusted

with an internally mounted Allen key.

The RCK manual of 1944, lists a number of standard VHF frequencies for

which crystals were available.

Frequencies (in Mcs) listed are as follows:

116.10 117.90 119.34 121.50 123.66 124.02 124.38

126.18 128.70 140.58 140.76 140.94 141.12 142.02

142.56 142.74 143.28 143.64 144.00 144.36 146.16 147.96

149.49 151.20

The following standard RCN crystal frequencies

were available for the RCK receiver.

(Photo by Jerry Proc) |

| 1.1.9 - FR12-TH Transmitter/Receiver

Made by Canadian Marconi in the early 1940's the FR12 was a three mode

transceiver - CW, MCW and radio telephone. Power input was 15 watts on

CW, less on MCW and even less on phone. It was capable of transmitting

on low wave (375 to 580 kc) or short wave (1700 to 4200 kc) depending on

the model type. On low wave, the set had a range of about 20 miles. On

receive, it was capable of continuous tuning from 300 to 4200 kc. The letter

H in the model number indicates that the remote control option was installed,

however, it was not compatible with HAIDA's Radio Remote Control System

and was not used.

Made by Canadian Marconi in the early 1940's the FR12 was a three mode

transceiver - CW, MCW and radio telephone. Power input was 15 watts on

CW, less on MCW and even less on phone. It was capable of transmitting

on low wave (375 to 580 kc) or short wave (1700 to 4200 kc) depending on

the model type. On low wave, the set had a range of about 20 miles. On

receive, it was capable of continuous tuning from 300 to 4200 kc. The letter

H in the model number indicates that the remote control option was installed,

however, it was not compatible with HAIDA's Radio Remote Control System

and was not used.

The following standard RCN crystal frequencies

were available for the FR12 transmitter/receiver.(High frequency)

The following standard RCN crystal

frequencies were available for the FR12 transmitter/receiver.(Low frequency)

Under normal use, the FR12 would be used to communicate with merchant

ships or the Naval Administrative Net. Pictures taken in the 1950's show

the handset installed, so it was definitely used on voice. Emergency communications

could be provided by this unit if all else failed since it only operated

from a 12 volt DC power source. The receiver section consisted of a five

tube superheterodyne design with the ability to continuously tune the range

of 300 to 4200 kc in three bands. To simplify the overall design, there

was no direct frequency readout for the receiver. Instead, a circular logging

scale dial was provided. It was necessary to calibrate the dial, and record

the readings in advance.

In the transmitter section, there was an oscillator, a modulator and

a dual power output stage. One of four, selectable, internally mounted

crystals determined the operating frequency. In order to activate the modulator,

one simply inserted the handset plug into the front panel socket. The microphone

in the handset provided the interlock for the modulator. If this was done

while the Dynamotor was running, a noticeable slow down of the Dynamotor

could be heard.

Power for the FR12 could be provided by one of two modes. In standby

mode, the filament circuit for the transmitting tubes gets disabled. Filament

power for the receiver would be provided from the main battery. The 180

volt B+ line for the receiver would be furnished from four, external, 45

volt dry batteries wired in series. Standby mode would dramatically increase

the life of the main battery. In normal mode, all power for the receiver

and transmitter was provided by the main battery. An internal Dynamotor

produced high tension for the transmitter but it had to be inspected after

every 500 hours of operation. Input power to the FR12 was 12 volts DC at

6 amps on receive and 13 amps on transmit when used in normal mode. On

HAIDA, the antenna for the FR12 was a sloping, twenty seven foot vertical

wire designated as the PORT OUTER VERTICAL.

Al Goodwin of Dartmouth N.S. did some range experiments with the FR12.

"It was sent away in a sea boat on a couple of occasions. In those days,

we didn't have commercial mobile antennas available to us, so we rigged

up a 35 foot whip antenna. The exercise was not deemed a success as we

lost communications around five miles. On HAIDA, we used this set for both

AM and CW communications. For CW operation, we would have to attach a key

with a very long lead. In an unusual case, the late Keith Lake (VE1PX)

used the FR12 to modulate the Marconi PV500 thus giving it AM capability

for use on the amateur bands. He put out quite a strong signal compared

to the 30 watts of the Marconi CM11". (Photo by Jerry Proc) |

1.1.11 - Remote Control Unit (RCU)

|

|

| RCU with clamshell closed up. |

RCU with clamshell open. |

| This was a device that allowed a radio channel to be controlled

from a remote location on the ship. RCU's come in single channel and four

channel versions, with and without weatherproof covers. A single channel

unit only had the capability of controlling one radio channel, while the

four channel unit could switch between, and control, up to four radio channels.

An RCU supported both voice and CW operation and provided the functions

of an intercom.

The RCU also keys the transmitter via the Channel Amplifier when sending

Morse code. . The maximum Morse speed is 100 characters per second depending

on cable length from the RCU to the transmitter. .

Every system has limitations, so the Radiomen had to observe some operating

precautions. In normal operation, the manufacturer suggested that a maximum

for four RCU's be connected to any given radio channel. Intercom functions

were limited to those RCU's connected to the same radio channel. It was

also possible to connect more than one RCU to a radio channel. Despite

these minor restrictions, the system worked very well. (Photo by Jerry

Proc)

A wiring diagram for the RCU handset can

be found here, |

|

| This RCU to CSU interconnect diagram shows

the locations of the RCUs. Select

this link for a PDF version of the file. (Drawn by Jerry Proc) |

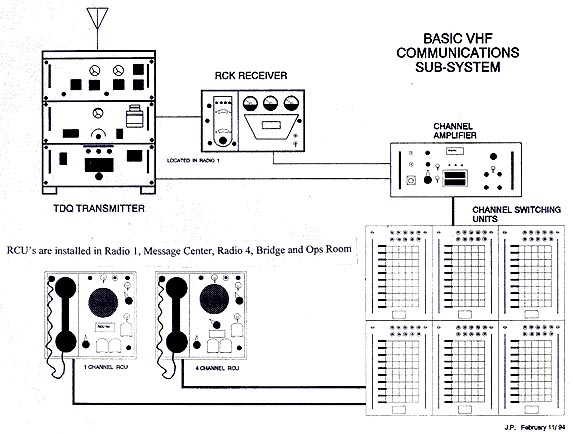

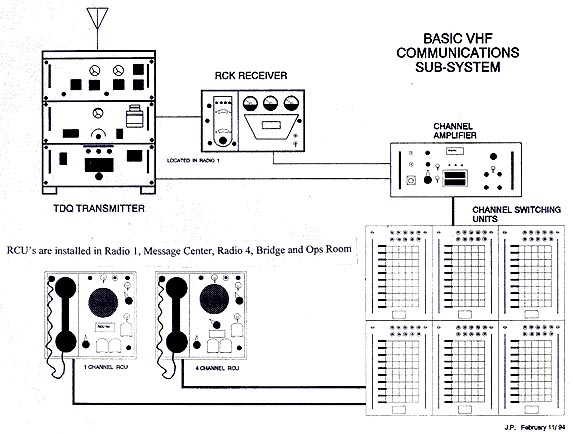

| 1.1.12 - TDQ Transmitter

First built for the U.S. Navy in May of 1943, this unit was capable of

voice or MCW transmissions in the 115 to 156 Mc band running 45 watts continuous

power.

Any one of four selectable crystals determined the frequency of operation.

The following standard RCN crystal frequencies

were available for the TDQ transmitter.

First built for the U.S. Navy in May of 1943, this unit was capable of

voice or MCW transmissions in the 115 to 156 Mc band running 45 watts continuous

power.

Any one of four selectable crystals determined the frequency of operation.

The following standard RCN crystal frequencies

were available for the TDQ transmitter.

Before the days of UHF equipment, destroyers were fitted with a pair

of TDQ/RCK sets. These were used for operations circuits such as "Plot

Primary". When the RCN followed the United States Navy to UHF voice, the

TDQ/RCK was left behind as the only VHF set capable of monitoring and communicating

with aircraft, other ships, yachts and harbour facilities. The basic role

for this set became that of 'guard' for the VHF distress frequency of 121.5

MHz. The TDQ could be remotely operated through the shipborne radio remote

control system. Weighing in at 285 pounds, it was extremely heavy by today's

standards. (Photo by Jerry Proc) |

|

| VHF System Diagram. Select

this link for a PDF version of this drawing. (Drawn by Jerry Proc) |

| 1.1.13 - TED3 (AN/URT-502) Transmitter

The TED3 was a low power UHF transmitter capable of AM or MCW operation

in the 225 to 400 Mc band. TED transmitters were designated as AN/URT-502A

by the RCN and were built by Westinghouse in Hamilton Ontario and the RCA

Victor Company, Montreal. Nevada Air Products and RCA Victor produced URT502B's.

Each TED3 in Radio 1 was connected to a separate, weatherproof, UHF dipole

antenna located on the lower yardarm of the foremast. The designated model

number for the antenna is AT-150/SRC. TED3's were introduced into service

in 1952.

The TED3 was a low power UHF transmitter capable of AM or MCW operation

in the 225 to 400 Mc band. TED transmitters were designated as AN/URT-502A

by the RCN and were built by Westinghouse in Hamilton Ontario and the RCA

Victor Company, Montreal. Nevada Air Products and RCA Victor produced URT502B's.

Each TED3 in Radio 1 was connected to a separate, weatherproof, UHF dipole

antenna located on the lower yardarm of the foremast. The designated model

number for the antenna is AT-150/SRC. TED3's were introduced into service

in 1952.

A TED3 was always used in conjunction with a Channel Amplifier Unit

and a URR35 receiver. This combination of equipment provided a "UHF communications

channel". Radio 1 provided three out of the seven UHF communication channels

aboard HAIDA, while Radio 3 provided the other four. Surprisingly, TED's

were routinely used in MCW mode on the intership Task Group Common circuit.

TED's had small, axial crystals which fit into a four position crystal

holder located behind a hinged door. Radiomen had to carry out frequency

shifting drills which consisted of quickly changing the whole set and it

could become very frustrating if a crystal was dropped. It would invariably

disappear under an equipment rack and would never roll back out!

The following standard RCN crystal frequencies

were

available for the TED3 (AN/URT-502) transmitter. Frequencies

marked with an asteriskare for use by the CNEL. (Canadian Navy Electrical

Laboratories) |

1.1.14 - Frequency Measuring Equipment

|

| BC221 photo courtesy RCN. |

BC-221

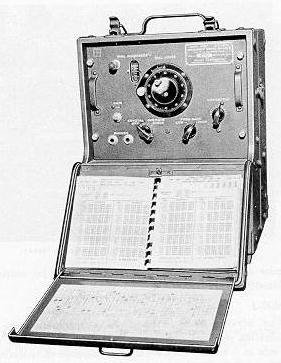

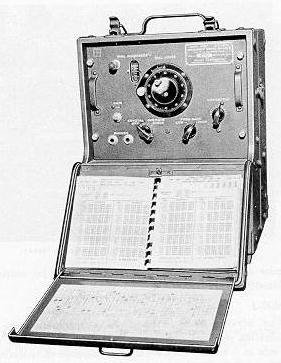

The BC221-M Frequency Meter was designed to provide a means of accurately

calibrating transmitting and receiving equipment within the frequency range

of 125 kc to 20 Mc where no crystal was available for a radio channel.

This meter is a portable heterodyne type with a built in crystal calibrator.

A unique calibration book was prepared for each unit and it could not be

interchanged with other BC221 meters. Power was provided by a dual voltage

dry battery.

AN/URM-32

Eventually the BC221-M was superseded by the AN/URM 32 Frequency Meter.

This unit was used to calibrate transmitters in the frequency range of

125 kHz to 1000 MHz when crystals were not available. Unlike the older

BC221, the URM 32 could be powered from 120 VAC or batteries. In addition

to its use as a frequency meter, this unit also had the capabilities of

a signal generator.

|

| Dave Blais, RCN radioman at the time, adjusts the URM-32 frequency

meter aboard HMCS Restigouche in 1959. (RCN photo from the collection

of Dave Blais) |

Click on photo to enlarge

|

MORE RADIO 1 PHOTOS

|

|

Forward view in March 1961: LSSG Harold

Stratton has a chokehold on Ronald Yaschuk (foreground). At the left of

the photo is the the bulkhead partition which was extended in 1962 to enclose

the Message Center. It must have been very noisy back then with the Teletype

machines chattering away and without sound isolation. (Photo submitted

by Ronald Yaschuk e-mail: ronlynn(at)rogers.com) |

|

A starboard/forward view in 1960: This

entire area was reconfigured when the navy fitted crypto equipment aboard

the fleet in 1962. The rack at the back was the radioteletype (RATT) bay

and looks very similar to the way it does today. The big black box on the

starboard bulkhead was the LF receiver used to copy the broadcast to submarines.

(Photo

by Ronald Yaschuk) |

|

A starboard/aft view in 1960: ABRM Ron

Stebner. He passed away in 1971 at age 27. (Photo by Ronald Yaschuk) |

|

A starboard/aft view in 1960: ABRM Ron

Stebner and LSSG Harold Stratton in a lighter moment. There were

additional modifications made to this corner after 1960. The Marconi FR12

transmitter receiver (barely visible) was moved to its own shelf, affixed

to the starboard bulkhead and a storage area was fitted to the top-rear

of the desk. Note the stateboad affixed to the power panel. (Photo

by Ronald Yaschuk) |

|

Aft view in March, 1961: ABRM Ron

Stebner poses next to the Marconi CM11. The section of the room remained

unchanged until HAIDA paid off. (Photo by Ronald Yaschuk) |

OTHER EQUIPMENT

AID Speaker

Radio 1 is fitted with one AID speaker and fitted to it's right is a

boom mounted, AID microphone. The 1962 drawing does not show a microphone

fitted, so this one remains a mystery.

Amateur Radio

Al Goodwin of Dartmouth N.S., served aboard HAIDA as the POTEL (senior

radio operator) from May of 1960 until she was paid off in October of 1963.

Al recollects some memories from this period. "I operated the amateur radio

station from early 1962 when I first received my ticket until we paid her

off. At one time, we had five operators working the bands and that was

probably a record number for one ship. For a receiver, I removed the Hammarlund

SP600 in Radio 4 and used it with either a Marconi CM11 or PV500 transmitter.

A VE0 call was very rare in those days and one CQ brought back a 'pileup'.

One thing still sticks out from this period. The CO thought that operating

an amateur station was really neat. He used to bring his guests into Radio

1 and show them the QSL cards that were displayed on the aft side of the

message centre bulkhead. One day, he noticed a QSL card from Russia and

asked - 'What would you talk to him about?' I replied 'Crypto codes - of

course', a remark that I passed during the height of the Cold War".

Clocks

AC power to the radio room was notoriously unstable and the cyclic

output of the alternators was even worse. This prevented the use of electric

clocks whose synchronous motors depended on precise regulation of the frequency

of the input power. Although marginally better, Seth Thomas mechanical

clocks were used, but they too were somewhat erratic. These clocks had

to be set to time stations WWV or WWVH daily.

With reference to radio room clocks marked with the red silent periods

for 500 kHz distress ( as above), some ships did have clocks with the markings

while others did not. Some also included the black silent periods for 2182

kHz AM distress on the hour and half hour. These markings were not universal

and in some cases the clocks had no silent period markings at all. Fred

Ware , a WWII era Telegraphist could not recall a single ship that he served

in where the radio room was fitted with a clock with the silent periods.

|

| This is a typical example of saship's radio room clock before

1947. In that year, 2182 KHz was added to become the International

voce distress frequency, so "green" three minute silent periods were

added at the hour and half hour intervals. Wedges could also be found

in red/green, red/blue (Scandinavia) and red/pink (USSR) colours.

(Photo via E-bay).

Those red bars are 4 seconds long and are separated by spaces of 1 second

in length to assist the radio operator in sending an automatic alarm signal

by using a hand key if the automatic key failed to work. |

|

| This radio room clock (?/) sports a Roman numeral face. There

are two red lines to denote the 500 KHz silent periods. It is not known

if these are original or if they were added by some radio operator. Sestral

of England built this clock for HMS Chatham and one of the

distributors was "R.F. BOVEY -VANCOUVER B.C." (Photo and copy

via E-bay) |

CLOCK SPECS

These were the specifications for a ship's radio room clock as dictated

by Maritime law.

80.828 Radiotelegraph Station Clock.

A working clock equipped with a sweep seconds hand and having a dial

not less than 12.7 cm (5 inches) in diameter, the face of which is marked

to indicate the silence periods prescribed for the radiotelegraph service

by the International Radio Regulations, must be provided. It must be securely

mounted in the radiotelegraph operating room in such a position that the

entire dial can be clearly observed by the radio officer from the normal

radiotelegraph operating position, from the operating position where the

international radiotelegraph alarm signal would ordinarily be transmitted

by hand, and from the position used for testing the auto alarm (if installed).

If a separate emergency radiotelegraph operating room is provided, the

requirements of this section apply to it also.

[51 FR 31213, Sept. 2, 1986, as amended at 58 FR 44953, Aug. 25, 1993]

|

If anyone wishes to create their own radio room

clock, this PDF file might be suitable. The face is 4.5 inches in diameter.

Click on the graphic to launch the file.The drawing can be scaled with

software such as Inkscape for any size. The pdf file contains vector

art not bitmap art which means that the clock face can be scaled for any

size from a watch face to an outdoor clock face.

For 500 KHz., silent periods were always a quarter and a quarter

after the hour for a 3 minute duration. For 2181 KHz, it for 3 minutes

past the hour and half hour. The silent periods can be marked in different

colours depending on the manufacturer of the clock. (Drawn By David

Ring Jr. N1EA) |

COAX CABLE

With the exception of CM11#3 in Radio 2, all the CM11s and UHF

transmitter/receivers are connected to their respective antennas with RG-18

coax cable. RG-18 is about 1 inch overall diameter. The centre conductor

is solid copper, about 1/8 inch in diameter. Surrounding it is the dielectric

and the electrical braid. The coax itself is covered with a protective

braid to resist damage from shrapnel. RG-18A/U has an impedance of

52 ohms and has been replaced by RG-219/U whose voltage rating is 11 KV.

Crystal Cabinet

The crystal cabinet, mounted above the TDQ transmitter, was used to

store all of the crystals that would be required to fulfil any Communications

Plan. Keith Kennedy of Surrey B.C recollects details about the cabinet.

"Physically, the cabinet was of wood or aluminum construction, and was

as wide as the TDQ transmitter and two thirds of its height. When the ship

was in harbour, the front doors were secured with a bar and combination

lock. Internally, there were six to eight slide out plywood shelves or

trays with numerous felt lined pockets approximately two inches square.

Each pocket contained two crystals - one for service and one was a backup.

The transmitter and receiver crystals were kept on separate shelves to

prevent them from getting mixed up. For the most part, the cabinet was

used to store crystals for TED/URR type equipment, but some CM11 transmitter

and CSR5 receiver crystals were also stored here ".

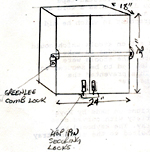

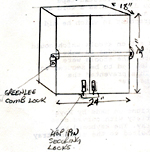

|

The crystal cabinet aboard HAIDA is missing.

Radioman Keith Kennrdy provides this sketch of how it looked physically

and the approximate dimensions. The section of the bulkhead where the cabinet

was mounted has not discloured at the same rate as the remainder of the

bulkhead. The lack of discoloration thus provides for the actual

width and height dimensions of the cabinet. If a replica cabinet were to

be built, the dimensions of the non faded area would need to be followed.

Click on image to enlarge. If anyone with woodworking skills wants to build

a replacement cabinet, contact : Jerry.Proc@sympatico.ca |

CW Keys

Two types of straight keys were used for CW transmission. One was the

Speed-x square, chrome based type. The other was the tear- drop shaped,

black wrinkle finish base variety. Keys were mounted on a clear plastic

plate which straddled a rectangular hole located in a bay, at the right

side of the operating desk. Electrical connections were made to the KEY

input of the Remote Control Units next to the CSR 5A receivers. In HAIDA's

case, it's suspected that the keys were hardwired into the RCU.

|

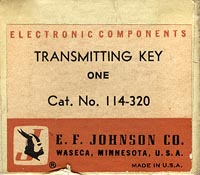

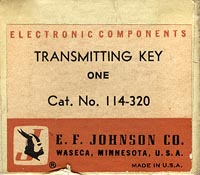

| This key is the Speed-X Model 320-001 made by the E.F. Johnson Company

and was used by the RCN during the 1950's and 1960's. The example in the

photo was made in 1967 and the RCN part number was 114-320. (Photo courtesy

of Morse Express ) |

|

| This is the box end for the above key. (Image courtesy Spud Roscoe) |

Headphones

Headphones that were in general use in the 1950' had bakelite earpieces

cushioned by soft rubber coated pads. The two spring bands connecting the

two earpieces was covered with stitched, tan coloured leather Each

headphone assembly bore two markings: MX- 41/AR and ANB-H-1. It is not

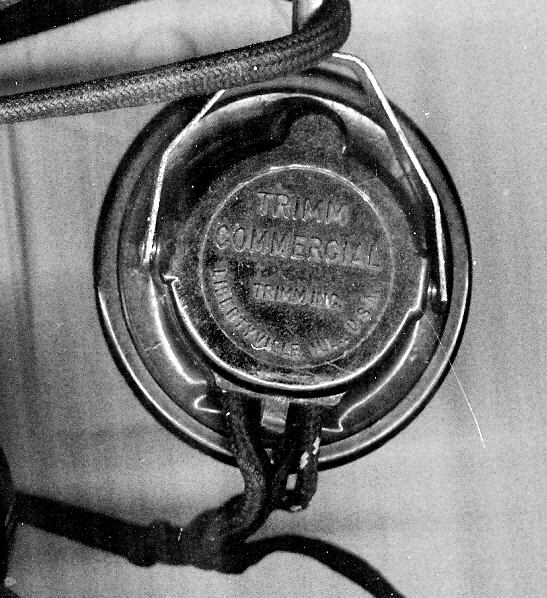

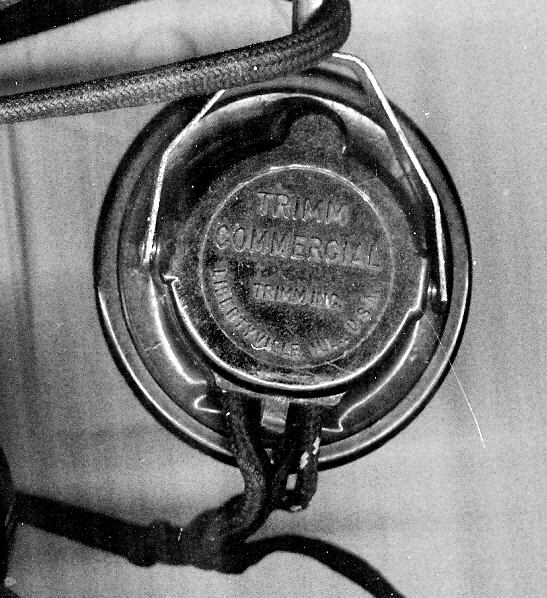

known who manufactured these two specific models. By the 1962, the RCN

switched over to headphones made by the TRIMM company. These did not have

earpiece cushions.

|

| These Headphones, made by TRIMM, were in use

by the RCN in 1962 and would have been used specifically aboard HMCS HAIDA.

(Donated

by: Wayne Blenkhorn VE1BAB. Photo by Jerry Proc)

Spud Roscoe adds: "We did not wear the TRIMM headphones over the ears.

Rather, they were placed on the head just slightly forward of the ears

and because we were also copying fast Russian operators, we kept the audio

gain up so one and all could hear it. Some had it so loud you could hear

it a mile away" |

|

| Headphone markings: TRIMM Commercial

Libertyville Ill. (Photo by Jerry Proc) |

Metal Desks and Chairs

Metal desks that were used for the operating consoles were supplied

by Eaton's of Canada but it is not known whether they could be purchased

by the general public. The original colour is a metallic flake green finish

as evidenced by looking underneath some of the sliding typewriter trays.

Over the years, the desks have been repainted in the routine colour of

navy grey. On HAIDA, all of the slide out drawers in the desks are missing

the locking latches. These would be essential to have in a rough sea.

Gregory McLean of Abbotsford B.C. recalls, with great detail, the furnishings

and the some of the routines in Radio 1. "The chairs used in some radio

rooms of the 1950's were swivelling arm chairs. They were of robust construction,

with padded backs and tubular sides. The bases of these chairs were bolted

to the deck and a pivoting steel shaft was affixed to the underside of

the seat. This shaft was fitted into the base, thus giving the chair firm

support and allowing the operator to swivel 360 degrees. This type of seating

arrangement persisted in some ships and is still in use today.

To a great extent, it was felt that the swivel chair was superior to

the 'chair and chain' technique which was used on HAIDA at the time of

her de-commissioning. The tubular sides and the anchored base gave firm

support in rough seas and was easy to use. On the chained chairs, the chair

did not move once the chain was secured making it difficult to get ones

legs out from under the desk.

Decks on ships were scrubbed every day, but special house cleaning was

done for Captain's rounds. Radio 1 "scrub out" was in the middle or morning

watch when the radio traffic volume was least. At that time, the swivel

chairs were pulled from their bases and set to one side. The 'broadcast'

chair was left to last in case traffic resumed".

When seamen were not on radio watch, spare hours were filled with maintenance,

book amendments, cleaning stations and working part ship (painting, scraping

etc).

|

| 1950s and 1960s: These were the style of chairs that would be

found aboard Radio 1 in HMCS HAIDA What is there today came from

a post 1963 ship. In the fireground is ABRM Ron Stebner. (Photo via

Ronald Yaschuk) |

POWER

Mounted on the aft bulkhead, starboard side of Radio 1, is the DC power

distribution panel for the equipment in the room which was capable of operation

from a DC power source in case of emergency. Emergency power was provided

by a large battery bank positioned in the starboard passageway aft of the

bulkhead in Radio 1. This battery could be re-charged by the ship's electrical

system.

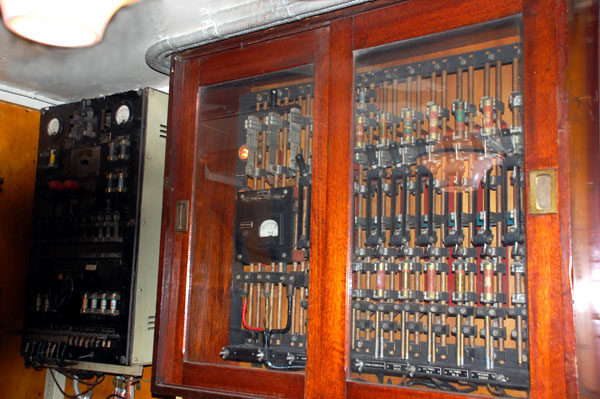

Adjacent to the DC panel, is the wood and glass encased AC distribution

panel. AC power for the equipment in Radio 1 was supplied from here. HAIDA

was originally fitted with a 225 VDC electrical system. Power was supplied

by two 200 kilowatt generators that were steam driven and two diesel driven

60 kilowatt units. As more and more American equipment was fitted in the

ship, it became necessary to produce 120 VAC 60 Hertz power. Lead case

cable was used in Canadian ship construction post-war as evidenced in the

four Canadian-built Tribals. Probably the first use of armoured cable was

in the 3"50 gun system (including gun drives, Mk63 GFCS and AN/SPG34 radar)

installed in Tribals around 1950

|

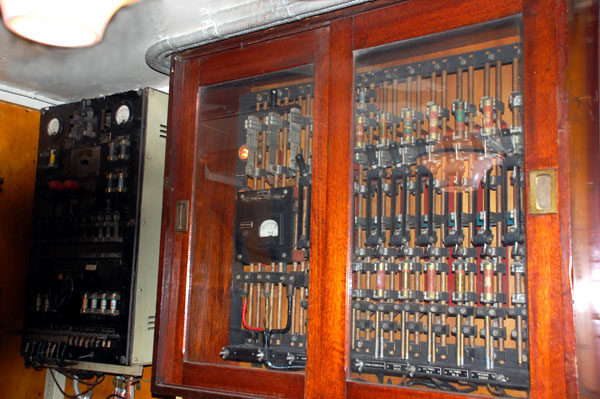

| The glass and wood panel at the right is the AC distribution panel

for Radio 1 and Radio 3. Feeding the panel is a 3 phase, 440 volt

Delta source which originates from the forward AC switch board in

the Electrical Workshop. The AC feed is at the lower left corner.

Power is then then distributed to the various branch circuits in

Radio 1 and Radio 3. Near the left top are two pilot lights

which indicate that the panel is live, however, only one of the lights

is visible in this view. (Photo by Jerry Proc) |

|

| This is the low voltage DC distribution panel It distributes

emergency DC power to whatever Radio 1 equipment had the capability to

operate from a low voltage DC source. The batteries that fed this panel

were located inside an enclosure which was affixed to the deck on the the

opposite side of the bulkhead. They would be recharged from the ships 220VDC

grid, This 220 volt feed is at the top of the panel. Note that the two

voltmeter switches atop the manel are missing. Click on image to enlarge.

(Photo by Jerry Proc)

From the markings on the tally plates, it appears that one CSR-5 receiver

and the FR-12 transmitter/receiver were connected to separate 12 V batteries.

There are markings that show the CM-11 being connected to a 24 battery

, however there is no motor -alternator set for the CM-11 in Radio 1. It

is suspected that the 24 V source for the CM11 may have been provisioned

from the low power room one deck below Radio 1.All the 24 volt wires are

cut with no loose wires underneath. |

|

| The batteries which fed the low power panel in Radio 1 were situated

in this enclosure. There are four 6 volt batteries.here. Each pair is wired

in series to produce 24VDC. Click on image to enlarge,. (Photo

by Jerry Proc) |

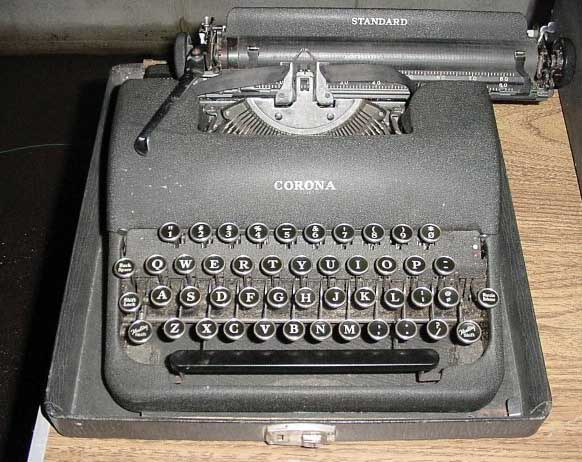

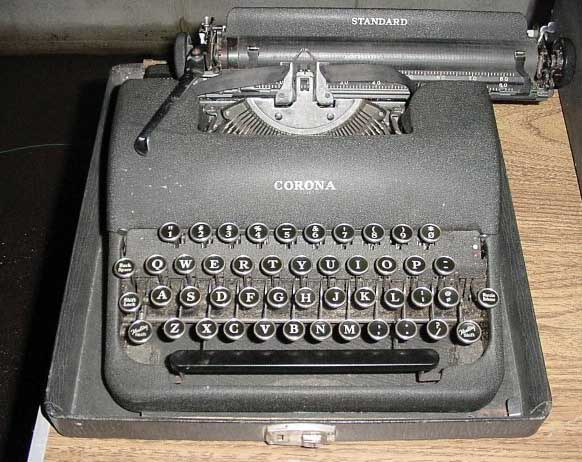

Telegraphic Typewriters

The typewriters used at the operating consoles were Royal or Remington

Telegraphic typewriters which could only print capital letters and some

special symbols. Two keys away, and to the right of the letter L was a

"dead" key which would print a line and then, without the carriage moving,

the operator could type an accented or Tiddley" (special) letter.

They were of the closed frame variety and painted in wrinkle finish

grey. The typewriter itself, was bolted to a sliding tray which was located

in the middle bay of the desk. Radiomen often referred to the typewriters

as "mills". In those days, the Royal or Remington typewriters looked sleek

and modern.

|

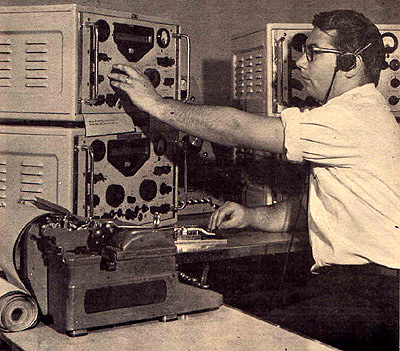

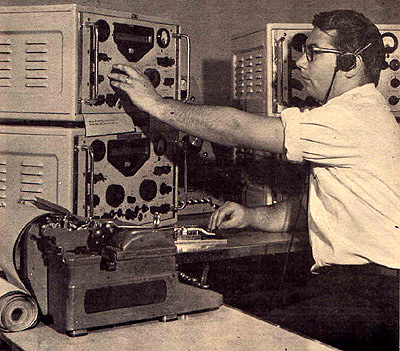

| Cpl B.A. Kelly of St. John's Nfld., operates a CW position at Canadian

Force Station Mill Cove N.S. in 1970. The typewriter in the photo was typical

of those used to copy CW in that period. (Photo courtesy Maritime Command

Trident, Nov. 1970) |

Often, an operator would spend long hours in continuous copy.

In order to make life more comfortable, he would pull the pins that restrained

the typewriter tray and move the tray out and slightly down. Everything

worked fine until a large wave hit the ship and in turn, it would cause

the typewriter to jump forward and unto the operators lap, often with undesirable

results. The unfortunate operator might be talking with a slightly high

pitched voice for a while. The paper supply for the typewriters consisted

of rolls which were mounted on a separate assembly within the centre bay

of the desk. Each roll of paper had metal caps inserted into the cardboard

core. Metal caps were saved as some of the paper rolls issued by the navy

did not come supplied with these. A thin steel rod was passed through holes

punched in the metal caps. The rod was then placed into slots on an angle

iron bolted inside the middle bay. This assembly allowed the paper to unroll

easily and kept the roll stable as the ship moved about in the sea. The

paper holder assembly was not part of the original desk and was added as

the need arose.

Generally speaking, one or two ply paper rolls were used for CW copy

but usually one. Teletype circuits, particularly broadcast, used two or

three ply but usually two. When supplies of one ply paper ran short, a

three ply roll would be rewound into individual two and one ply rolls.

These techniques were used because storage space on board was always at

a premium. Having 'stores' carry multipurpose items was most desirable.

Teletype ribbons were rewound onto typewriter spools because the ribbons

supplied for teletypes lasted much longer than the typewriter ribbons that

the navy purchased.

Three copy paper was used when the ship was the designated guard ship

in the group and copying the broadcast. The main problem with custom wound

rolls was the tendency for the paper to loose alignment. During a busy

watch, the operator had to align the sheets frequently. It was both the

fault of the platen pressure and the type of paper being used. This problem

became very critical when receiving a long message and the machine could

not be stopped to fix the paper. Needless to say, using more than two ply

paper was not popular.

Fanfold paper with perforations was tried at one point, but the paper

was difficult to set at the perf line. One message might be three lines

long while the following message might be three pages long. Some Radiomen

were accustomed to tear-off rolls and would tear off the sheet at the point

where the message ended. Trying to line up the perforations before the

next message started proved somewhat difficult.

Spud Roscoe offers this comment on typewriter installations. "A typewriter

in a ship had to be mounted so that the carriage ran fore and aft. A typewriter

with the carriage athwartships was more or less useless. When the ship

rolled you had to hold on to the carriage and move it with each letter.

When the typewriter was mounted so its carriage was fore and aft, it rarely

needed assistance unless the ship was really pitching badly".

Ronald Yaschuk describes a typewriter trick used in his era. "We attached

a heavy duty rubber band (of which we had plenty) to the carriage return

handle and the other end was fastened to the side of the typewriter bay.

This tensioned the platen to the left and offset the force of gravity when

the ship pitched. It served the purpose adequately".

In an effort to improve typing efficiency, the RCN evaluated telegraphic

typewriters whose keyboard layout resembled that of a teletype machine.

HMC Ships St. Croix and Swansea were among those who were chosen to receive

the initial batch of evaluation units. It was the intent of Canavhed (Canadian

Naval HQ) to standardize the "typing skill" of the Communication Trades

into one keyboard - basically that of the Teletype keyboard.

It was also intended to introduce a type of electro-mechanical typewriter,

which would eventually supersede the existing telegraphic typewriters in

copying or transcribing morse. As typewriters became unserviceable, they

would be replaced with the improved models. However, there was no intention

to use the new typewriters in the Communications School because the presence

of an on-site Queen's Printer typewriter repair shop made it virtually

impossible for a typewriter to require replacement. Training would continue

on the current type but, when new typewriters were encountered, it would

be up to the operator to make the keyboard conversion on his own time.

The new keyboard was to look like this:

Line 1

1 2 3 4 5 6 7 8 9 0

Line 2

Q W E R T Y U I O P NR

Line 3

A S D F G H J K L GR

Line 4 (Upper) " : ;

x ? , . /- (a dashed slash)

Line 4 (Lower) Z X C

V B N M / BT

NR = Station serial number

GR = Group

BT = Long pause

Dashed slash = ?

Sea trials indicated that some of the new typewriters were not standing

up. It is assumed that this initiative to develop a common keyboard

was ultimately abandoned.

|

| This telegraphic typewriter used by US Navy illustrates the upper

case only keyboard with the slashed zero character. (E-bay photo) |

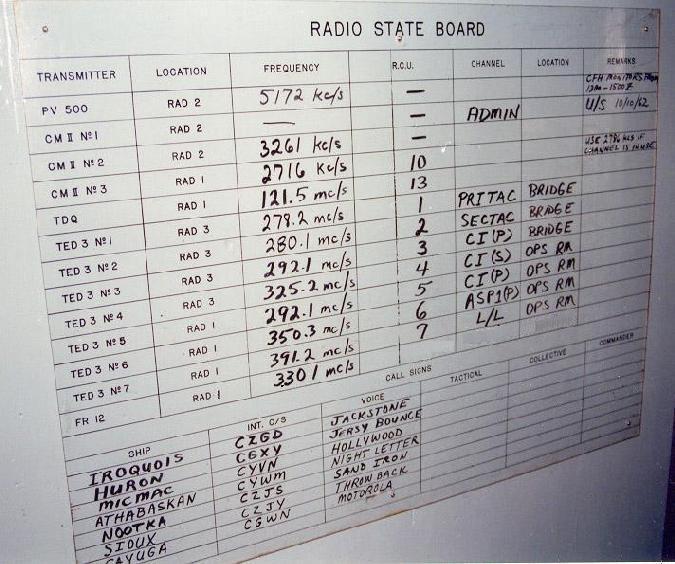

Radio Stateboard

Ron Yaschuk describes the rudimentary radio state board used in Radio

1 in 1960. "The stateboard was affixed to the front of the AC power panel

with metal clips. Templates were drawn up on white cardboard sheets which

were then sandwiched between two pieces of plexiglass. This enabled

the operators to keep track of the connections between Remote Control Units

and the radio circuits. An example of the makings would be:

Pri Tac - 273.6 MHZ - CAU# - OPS Room

Hbr Com - 283.4 MHZ - CAU# - Bridge etc., etc.

Each time a change in frequency was made or a Channel Amplifier Unit

changed position or designation, the stateboard would be wiped with paper

towel and the new designation, frequency and remarks would be updated

with grease pencil".

|

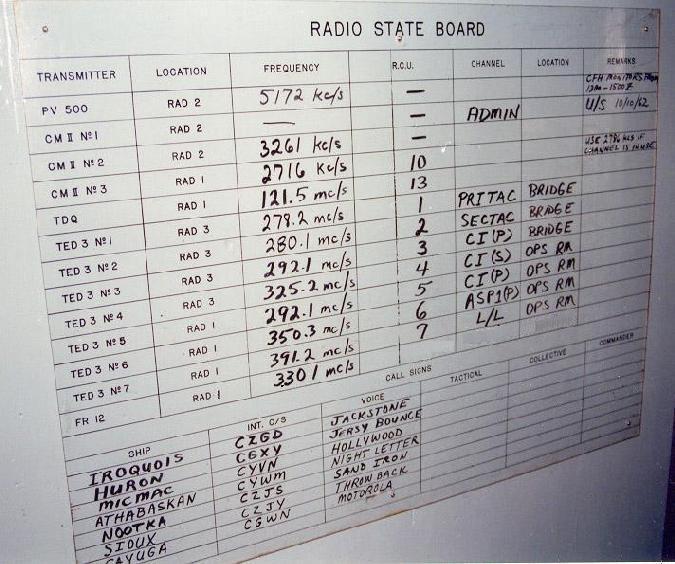

| This is an example of a typical radio stateboard. The board has

been marked up to be as authentic as possible to an early 1960's radio

environment. The actual stateboard in HAIDA was affixed to the main

fuse panel in Radio 1 bur it didn't resemvle this example.(Photo by

Jerry Proc) |

|

| This was the actual radio state board used

in HAIDA's Radio 1. It was attached to the AC distribution panel. |

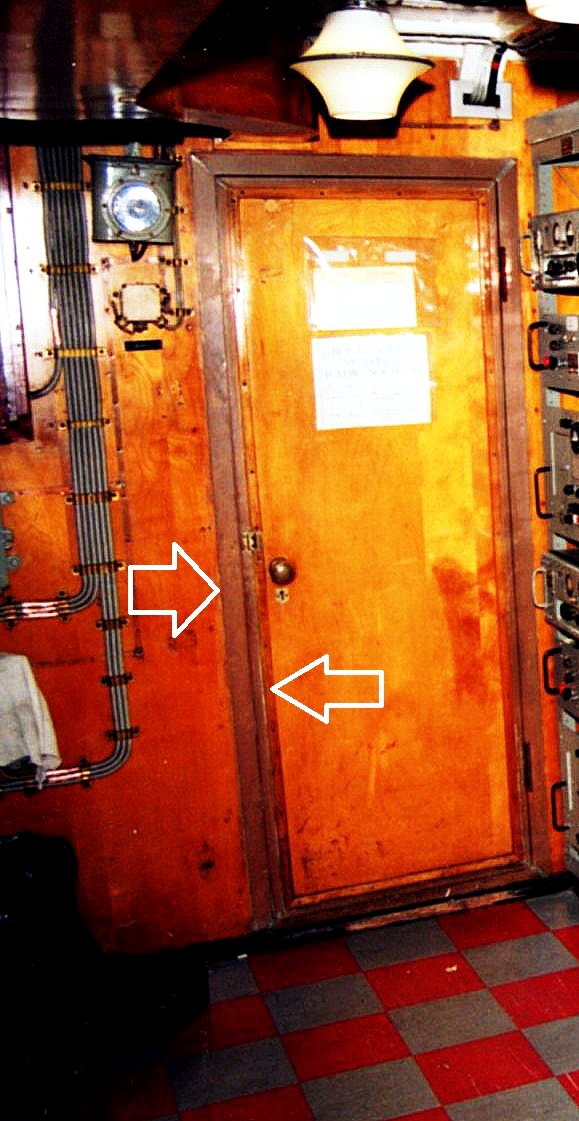

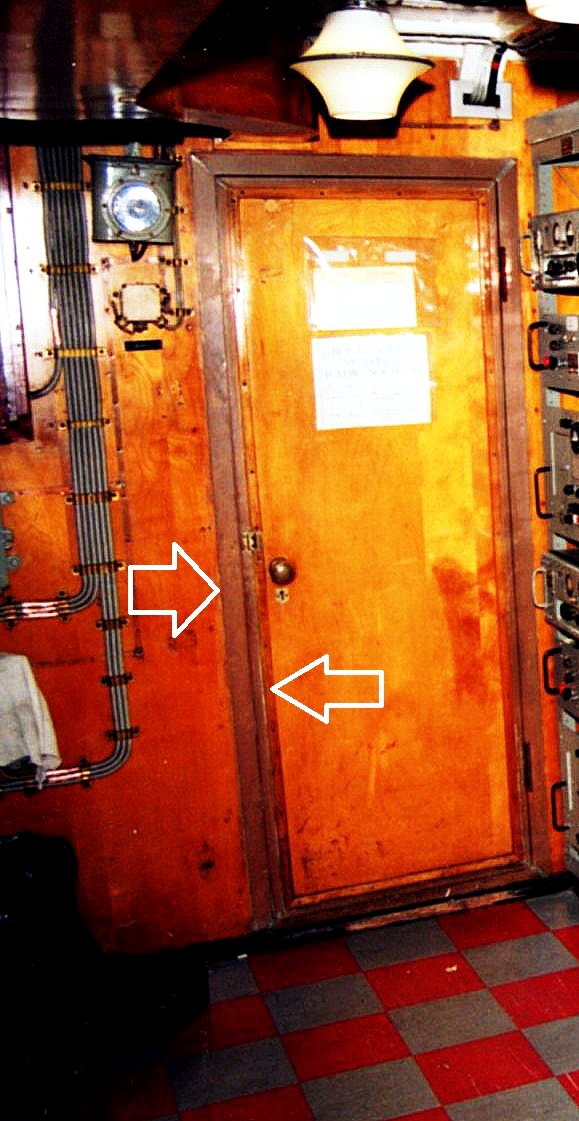

Shielding and Woodwork

Under the panelling, Radio 1 is encased with sheet copper which becomes

visible around the door frame for the Coding Office door. The purpose

of the copper shield is to minimize radio interference that is produced

from different parts of the ship and to ensure that radio frequency interference

generated within Radio 1 does not affect sensitive equipment in other parts

of the ship.

The air duct which spans the entire length of Radio 1 is comprised of

1/4 inch plywood only. There is no metal beneath. Besides being aesthetically

pleasing, it is believed that the duct was fabricated from wood to help

reduce the noise level of the airflow.

|

| In this example, the copper shielding peeks out on the door frame to

the Crypto office and the door itself. Radio 2 iand the Message Center

are shielded in a similar manner. Radio 3 and 4 did not need shielding

because they were surrounded by the steel in the bulkheads. |

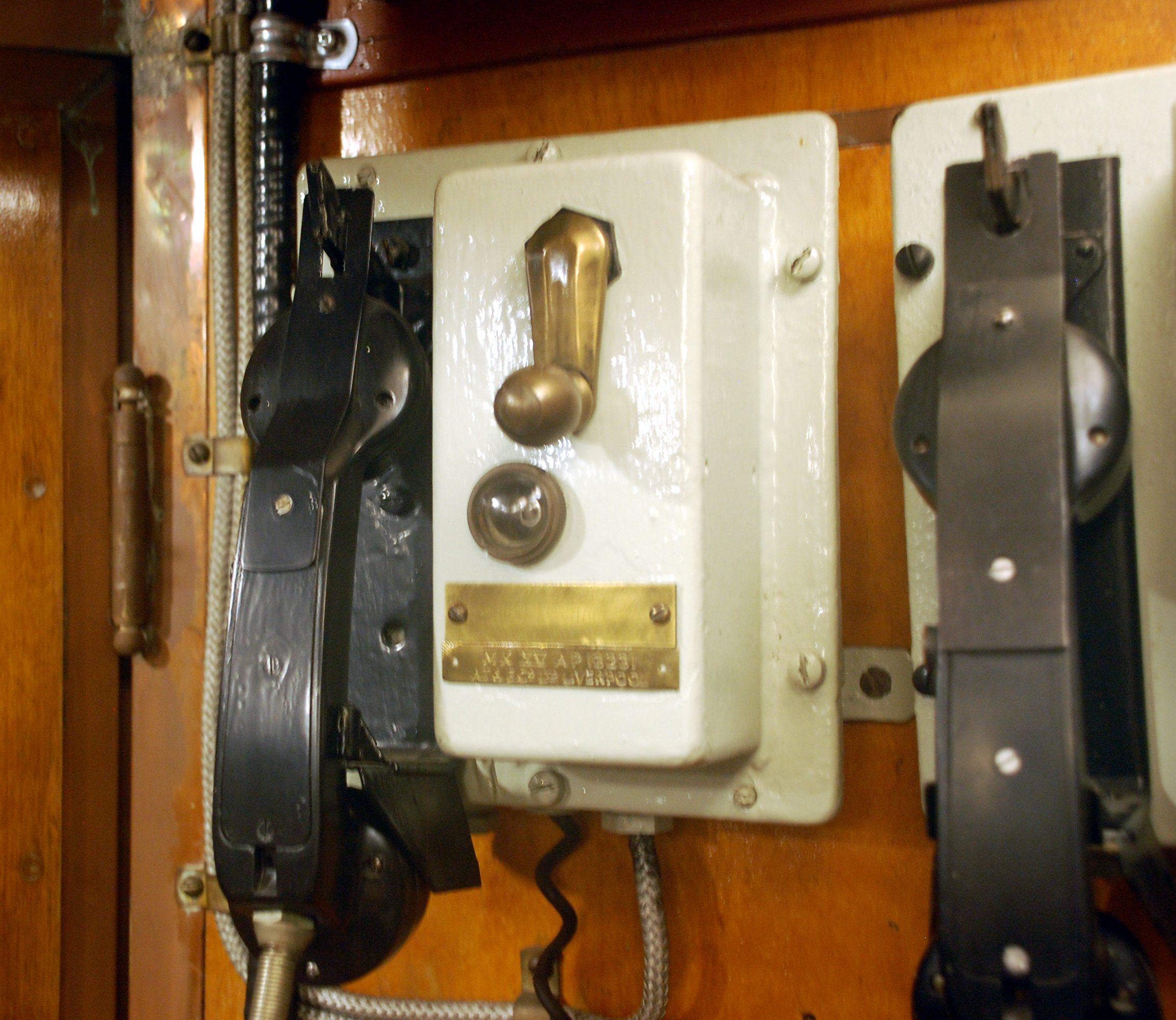

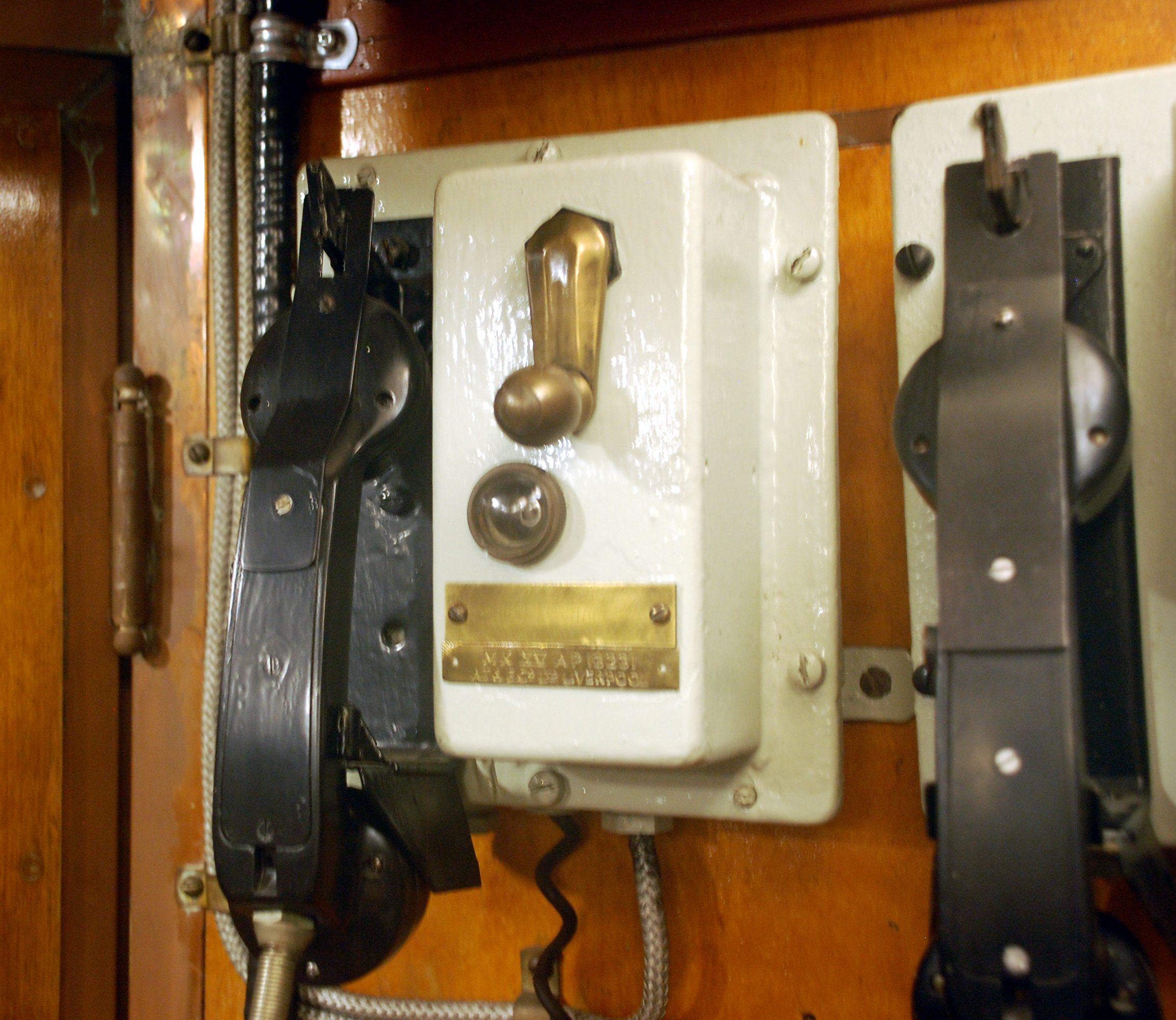

| Sound Powered Telephones

Installed throughout the ship are numerous sound powered telephones. Unlike

a regular telephone which needs 48 VDC to operate, these telephones convert

the energy of sound waves into electrical energy which powers the sets.

Installed throughout the ship are numerous sound powered telephones. Unlike

a regular telephone which needs 48 VDC to operate, these telephones convert

the energy of sound waves into electrical energy which powers the sets.

The actual efficiency of a sound powered link is about 25 db lower than

that of a regular carbon microphone system. This limits the sound powered

equipment to point-to-point applications and limited party line applications

where the line loss does not exceed 15 db. Because of the resonant characteristics

of the microphone and receiver units, the frequency response of the telephone

falls off sharply for frequencies above 2000 Hz.

There are two types of telephones installed on HAIDA. One type is the

single line set and the other type is a selectable, six line unit. To originate

a call on a single line set, the user turns the crank on the phone. This

sends a ring voltage down the line which powers a buzzer and illuminates

a neon lamp on the remote unit. The remote user than picks up the handset

and communication can be established with the use of push-to-talk switches.

Phones can be wired as party lines, so rotating the crank on one phone

makes all of the other phones ring. By using ringing codes, only a certain

phone will get answered. On a party line, the recipient of a call listens

for the correct ringing code then selects the proper line with a rotary

switch. The telephone system uses three wire, armoured cable for communication.

White is common, black is voice, and red is ring.

The photo illustrates a sound powered telephone in a badly deteriorated

state. After 6 to 8 hours labour, the phones were restored back to their

1960's condition. (Photo by Jerry Proc) |

|

|

| HAIDA's original telephones were Mk XV A/P 13231

manufactured by the Telephone Mfg. Company in London England.and also AT&E

in Liberpool./ These telephones stowed the handset by using a metal strap

over a hook. This is an example of a single line phone. (Photo by Jerry

Proc) |

At some later date , the navy modernized

the telephones by the addition of a handset stowage assembly It was made

my Measurement Engineering part number 5905-040-4281. Not all of

the telphones were modernized as shown above.. (Photo by Jerry

Proc) |

|

| All damage contols phones in HAIDA

were painted red. All of them would terminate on a panel in the Damage

Contol Office, (Photo by Jerry Proc) |

|

This is the nameplate for The Telephone Manufacturing

Company of London Eng;amd. |

|

This is the nameplate for the AT&E company

in Liverpool. |

Sound powered telephone schematic

(Mk 15)

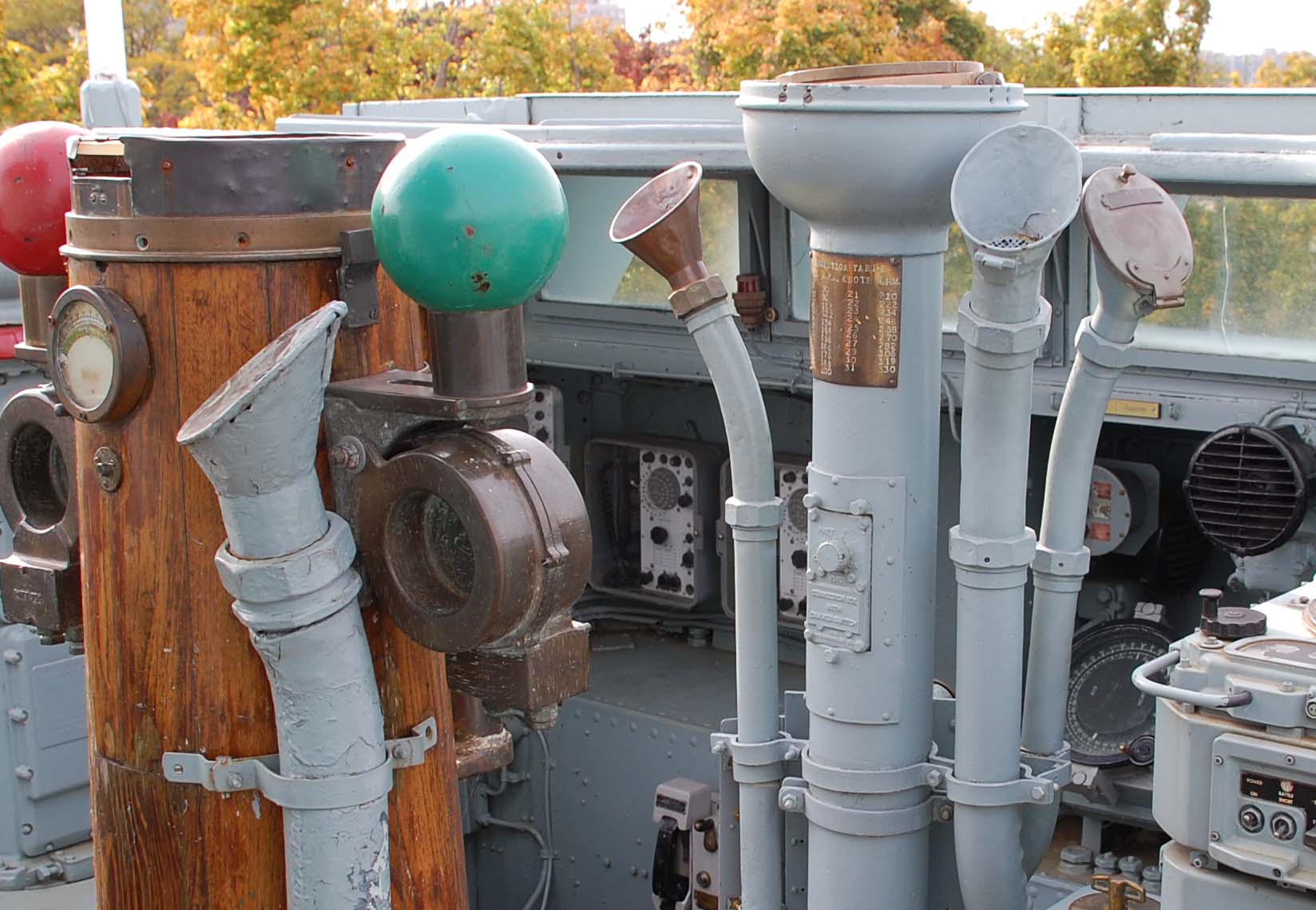

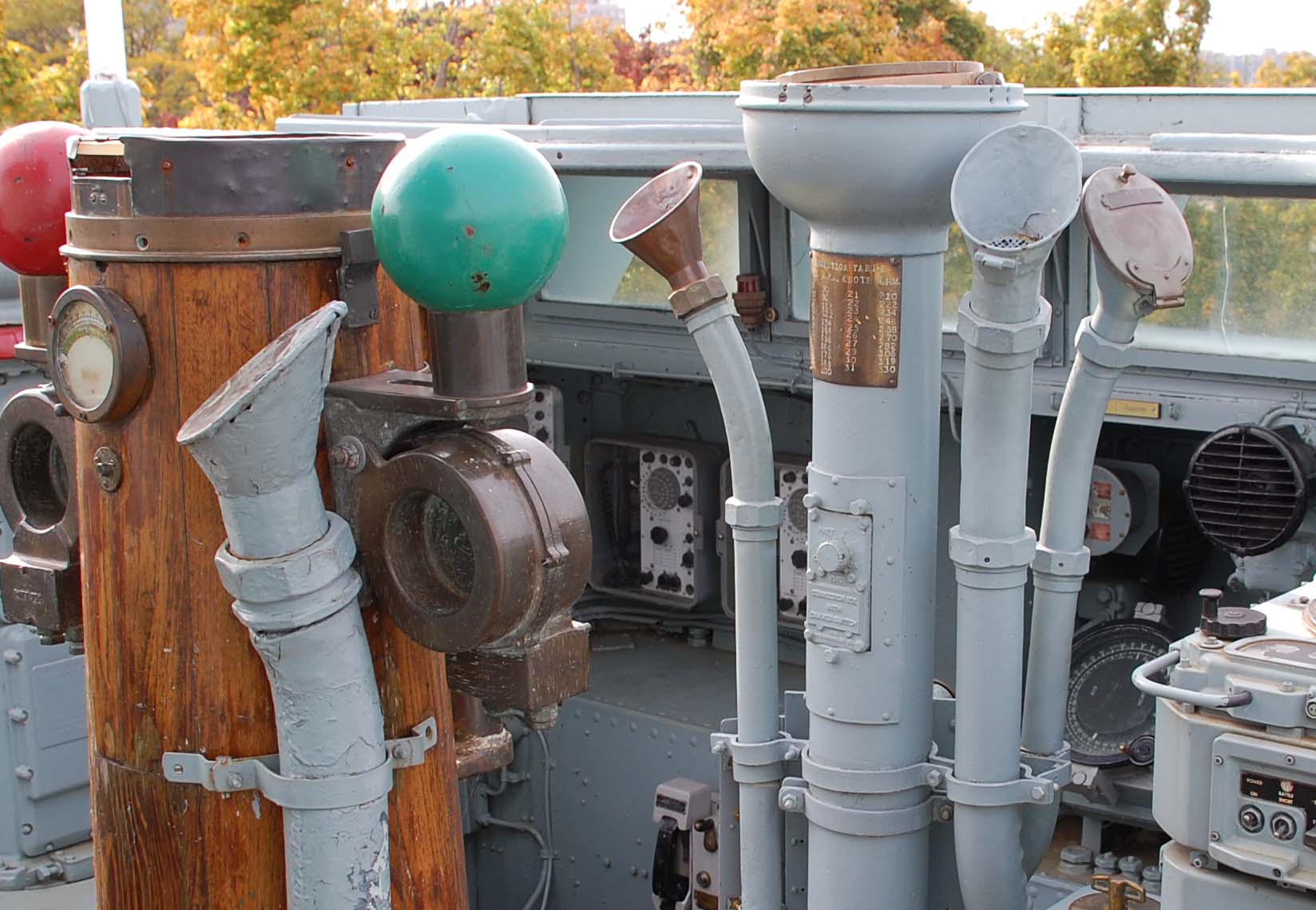

Voice Pipe

Besides being used for the transmission of voice traffic, the voice

pipe in Radio 1 was also used to move paper messages between the bridge

and radio room. Messages were placed in a small canister known as the 'bucket'.

This was raised and lowered from the bridge using a string known as Coston

Gunline. When there was a message destined for the bridge, the Radioman

signalled the bridge by pressing a switch next to the voice pipe. The party

on the bridge would then haul up the message. On occasion, the string would

break and the bucket became a 'bullet' which would then provide the 'receiver'

with a great surprise. Very strange items were known to travel through

those voice pipes.

|

| Voice pipe examples on HAIDA's bridge. The

voice pipe over the desk in Radio 1 is missing the flared section. (Photo

by Jerry Proc) |

A log of restoration activities

for HAIDA's Radio 1 can be found here. .

Credits:

1) Morse Express http://www.morsex.com/ccorner

2) Spud Roscoe <spudroscoe(at)eastlink.ca>

3) Dave Blais <brodger0131(at)rogers.com>

4) Colin Blackburn <acblack(at)shaw.ca>

5) David J.J. Ring, Jr. N1EA. Former radio officer

<n1ea@arrl.net>]

6) Wayne Blenkhorn VE1BAB <wayne(a)blenkhorn.ca

7) D.J.J. Ring, Jr. n1ea@arrl.net

Back to Table of Contents

Jan 16/25

Designed by the Canadian Signals Research and Development Establishment

and manufactured by Rogers Majestic starting in 1951, this was the first

Canadian developed and built post World War II military radio.

Designed by the Canadian Signals Research and Development Establishment

and manufactured by Rogers Majestic starting in 1951, this was the first

Canadian developed and built post World War II military radio.

First built by Canadian Marconi in 1942, this general coverage receiver

was capable of receiving AM and CW signals between 80 kc and 30 Mc with

the exception of the broadcast band. It had a tube count of thirteen and

weighed in at sixty eight pounds without power supply. CSR 5A's spent most

of their working life receiving the Fleet Broadcast or guarding the International

or marine distress frequencies. Each receiver was connected to its own

wall mounted speaker, but headphones were the order of the day. Loudspeakers

were used when one Radioman had to guard more than one frequency. This

was known as a loudspeaker watch.

First built by Canadian Marconi in 1942, this general coverage receiver

was capable of receiving AM and CW signals between 80 kc and 30 Mc with

the exception of the broadcast band. It had a tube count of thirteen and

weighed in at sixty eight pounds without power supply. CSR 5A's spent most

of their working life receiving the Fleet Broadcast or guarding the International

or marine distress frequencies. Each receiver was connected to its own

wall mounted speaker, but headphones were the order of the day. Loudspeakers

were used when one Radioman had to guard more than one frequency. This

was known as a loudspeaker watch.

Much rarer, is the Marconi CSR5Y, a variant adapted for diversity reception.

Rather than having a toggle switch for the AVC, a three position rotary

switch is used. It is marked DIV, OFF and INT. The Send/Rcv switch is eliminated

since the receiver is intended to be in receive mode all the time. There

is also a terminal strip on the rear of the chassis marked AVC. The AVC

was probably derived from an external comparator when in Diversity mode.

In all other respects, the Y variant is identical to its more common cousin.

The CSR5Y would mostly likely be found in a shore installation. (Photo

courtesy Meir Ben-Dror, WF2U)

Much rarer, is the Marconi CSR5Y, a variant adapted for diversity reception.

Rather than having a toggle switch for the AVC, a three position rotary

switch is used. It is marked DIV, OFF and INT. The Send/Rcv switch is eliminated

since the receiver is intended to be in receive mode all the time. There

is also a terminal strip on the rear of the chassis marked AVC. The AVC

was probably derived from an external comparator when in Diversity mode.

In all other respects, the Y variant is identical to its more common cousin.

The CSR5Y would mostly likely be found in a shore installation. (Photo

courtesy Meir Ben-Dror, WF2U)

Weighing in at 117 lbs, the RCK was a 'low radiation' VHF receiver built

by E.H. Scott Radio Laboratories during the 1940's. Copious use of RF shielding

helped contribute to its hefty weight. The RCK had four crystal controlled

channels and operated in conjunction with the TDQ transmitter in the 110

to 160 Mc radio band. Also, there were nine sockets for storing additional

crystals.

Weighing in at 117 lbs, the RCK was a 'low radiation' VHF receiver built

by E.H. Scott Radio Laboratories during the 1940's. Copious use of RF shielding

helped contribute to its hefty weight. The RCK had four crystal controlled

channels and operated in conjunction with the TDQ transmitter in the 110

to 160 Mc radio band. Also, there were nine sockets for storing additional

crystals.

Made by Canadian Marconi in the early 1940's the FR12 was a three mode

transceiver - CW, MCW and radio telephone. Power input was 15 watts on

CW, less on MCW and even less on phone. It was capable of transmitting

on low wave (375 to 580 kc) or short wave (1700 to 4200 kc) depending on

the model type. On low wave, the set had a range of about 20 miles. On

receive, it was capable of continuous tuning from 300 to 4200 kc. The letter

H in the model number indicates that the remote control option was installed,

however, it was not compatible with HAIDA's Radio Remote Control System

and was not used.

Made by Canadian Marconi in the early 1940's the FR12 was a three mode

transceiver - CW, MCW and radio telephone. Power input was 15 watts on

CW, less on MCW and even less on phone. It was capable of transmitting

on low wave (375 to 580 kc) or short wave (1700 to 4200 kc) depending on

the model type. On low wave, the set had a range of about 20 miles. On

receive, it was capable of continuous tuning from 300 to 4200 kc. The letter

H in the model number indicates that the remote control option was installed,

however, it was not compatible with HAIDA's Radio Remote Control System

and was not used.

First built for the U.S. Navy in May of 1943, this unit was capable of

voice or MCW transmissions in the 115 to 156 Mc band running 45 watts continuous

power.

Any one of four selectable crystals determined the frequency of operation.

The following standard

First built for the U.S. Navy in May of 1943, this unit was capable of