|

| This is the heart of the new degaussing system, the Degaussing Control Unit. (Image courtesy of SAM Electronics) |

Kingston Class Degaussing

Kingston-Class to Deploy State-of-the-Art Degaussing System

By T. Wayne McIsaac

Extracted from the Maritime Engineering Journal - Fall 2013

(Canada’s Naval Technical Forum)The 50-metre Kingston-class maritime coastal defence vessels (MCDVs) built in the mid-1990s have been stalwart in carrying out the roles for which they were designed. Manned mainly by the Naval Reserve, these 12 ships have been active, spending significantly more time at sea than originally envisaged. Especially now with the Halifax Class Modernization and Frigate Life Extension Project (HCM/FELEX) well under way, the MCDVs frequently find themselves doing patrols that were often performed by the heavier class ships.These versatile ships were designed to carry a number of different role-specific payloads. Although the Kingston-class is intended for operations in continental North American waters, some vessels have sailed across the Atlantic to Europe and as far away as Hawaii in the Pacific to participate in multinational training exercises. One of these payloads allows the MCDVs to conduct mechanical minesweeping. For a steel-hulled ship it is critical to have the ability to degauss – or remove the magnetism from – the vessel.

During construction all 12 ships were outfitted with a system of three degaussing coils running athwartship, longitudinally and vertically. However, only three of the ships were outfitted with the power supplies, controllers and masthead magnetometer. The original equipment manufacturer went out of business five years after delivery of the hardware, so parts were no longer available. Since part of the finishing of the job for the MCDV project was to fit degaussing control equipment in all ships, a capital project was stood up in 2009 to purchase and install degaussing equipment for the class.

Magnetic Fields of the Ship

Virtually any ship can be regarded as a ferromagnetic body, and placing this body into a magnetic field will change the field’s behaviour. Magnetic influence mines and other such weapons are triggered by this change. The overall strength of the change depends on the dimensions of the ship and its design, the permeability of the hull’s material and the equipment it has installed.

Generally, three different effects determine a ship’s total magnetic field as measured along its athwartship, longitudinal and vertical axes:

• Permanent magnetism caused by the structure of the ship, the fabrication method used and the equipment installed;

• Induced magnetism caused by the influence of the Earth’s magnetic field acting on the ferromagnetic mass of the

ship; and

• Eddy-current magnetism caused by the movement of the ship in the Earth’s magnetic field.Ships such as the Kingston-class require protection should they be required to operate in a mine danger area where magnetic influence mines might be present. For this they rely on their fitted degaussing system to minimize the magnetic field effects by generating counteracting fields.

The Kingston-class Degaussing System DEG COMP MOD 2

A request for proposals was generated through Public Works and Government Services Canada and put out to industry in 2011. A number of suppliers responded and the most technically compliant, lowest-cost bid was submitted by L-3 Communications MAPPS Inc. of Montreal. The design and build of the equipment was subcontracted to a sister company of the successful bidder – L-3 SAM Electronics in Hamburg, Germany. L-3 SAM has been a world leader in degaussing systems and has provided degaussing equipment to navies worldwide.

|

| This is the heart of the new degaussing system, the Degaussing Control Unit. (Image courtesy of SAM Electronics) |

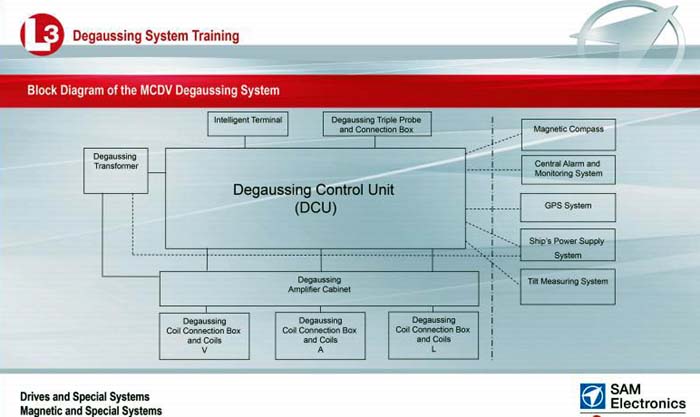

To meet the RCN’s technical statement of requirements, L-3 MAPPS provided a system that is currently in use by the German and Indian navies, among others. The system can be both automatic and manually controlled. The compensation fields are generated by means of a degaussing triple probe, the degaussing control unit (DCU), the degaussing amplifier cabinet, and the fitted coils.The DCU is the heart of the system, interfacing with all external data sources and the degaussing power supply units (DG-PSU). It provides all control and monitoring functions. The data containing permanent and variable magnetic fields are used to individually control the DG-PSUs to generate the required current output for each DG coil to compensate for the permanent and induced magnetic fields. The degaussing amplifier has three power supply components to energize the assigned degaussing coils which are identical apart from their individual coil supply voltageOne of the sources feeding the control unit is the triple probe located atop the mast and as far away from any magnetic material as possible. The probe has sensors associated with the ship’s three axes, and gathers information about the magnetic earth field components in the ship’s geographic location, as well as any fluctuations caused by the ship’s movement through the water.

New also, will be an intelligent terminal located on the bridge of Kingston-class vessels to replace the bridge degaussing control unit. This innovation, designed by L-3 SAM Electronics and deployed on the new German frigate and by the Indian Navy, offers command personnel a magnetic prediction of the ship according to operational conditions. The unit can stand alone or be part of the newly acquired DEG COMP MOD 2.

The intelligent terminal is designed for the following operational modes: signature prediction, optimization of ship’s magnetic signature, mine hazard calculation and remote control functions. The unit mimics the control panel. Information downloaded during ranging is stored and monitored by the IT system, allowing it to identify deficiencies in any coil, suggest a solution to optimize the coils and warn of impending problems related to the ship’s magnetic ability to go near a mine field. Operators believe that this equipment will enable better decision-making related to the safety of ship and crew when in hostile waters.

Project Status

Factory acceptance tests have been conducted on the degaussing equipment for the Kingston-class vessels. The majority of the components have been delivered, with the remainder expected to be handed over by September 2013. The equipment will be installed in the ships during planned short work periods, extended work periods and scheduled dockings.

An important part of the work in setting up the ships’ new degaussing system will be to deperm the vessels. This special procedure involves temporarily wrapping a ship in heavy gauge cables and pulsing high-energy electrical currents against the hull and superstructure to reduce the ship’s magnetic signature to as close to zero as possible. Afterward, the ship will be placed on a navy degaussing range where data on its magnetic signature can be gathered. This data will be uploaded to the onboard DCU so that controlled electrical currents can be sent to the fitted coils to obtain the best possible overall magnetic signature.

The plan is to have at least two ships installed, depermed and ranged by the end of 2013. The remaining ships will cycle through until all work is completed by the end of 2015. The degaussing team is confident that this new DEG COMP MOD 2 will provide the RCN with a sophisticated degaussing system design that will allow mine countermeasures to be carried out in all areas where Kingston-class ships are deployed, both now and in the future.

Wayne McIsaac is the project manager for the Kingston-class degaussing project in the Minor War Vessels section of DGMEPM. The other members of the team are LCdr Chad Naefken and contractor Paul Levasseur in the Directorate of Naval Requirements, Diane Plouffe in the Directorate of Maritime Procurement, and Jim Pederson in the Directorate Naval Platform Systems.

|

| Block diagram of the new degaussing system (Image courtesy of SAM Electronics) |

Contributors and Credits:1) Maritime Engineering Journal, Fall 2013